|

|

|

|

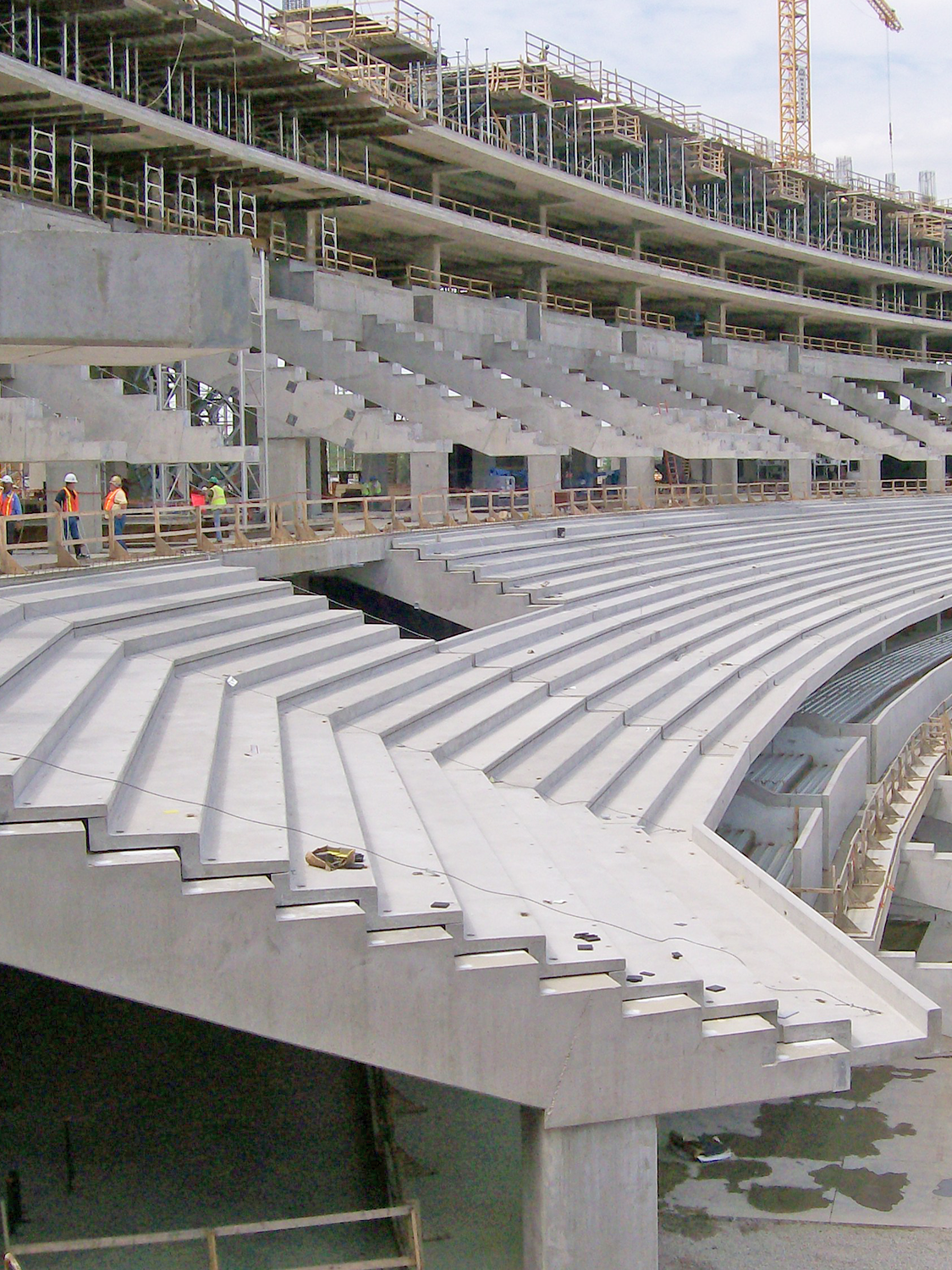

Precast Seating Risers

Heldenfels’ precast stadium seating risers form the foundation of spectator comfort and safety in venues across Texas, delivering the dimensional precision essential for proper sight lines and consistent row spacing. We produce both single and double riser configurations, allowing design flexibility for a variety of stadium layouts and seating systems.

Manufactured using specialized steel forms that maintain exact geometric tolerances, our risers eliminate the field adjustments and quality variations common with cast-in-place construction while reducing installation time by weeks. These prestressed components incorporate cast-in attachment points for seating systems, railings, and aisle lighting, ensuring secure mounting without field drilling into structural concrete.

The controlled manufacturing process produces consistent surface finishes and precise slopes for drainage, while the prestressed design allows for longer cantilever sections that reduce the number of supporting raker beams required. With successful installations in over 20 professional and high school stadiums, our seating risers have proven their ability to withstand decades of crowd loads, vibrations, and weather exposure while maintaining structural integrity and spectator safety in high-occupancy venues.

Product Information

Technical Specs

| Standard Sizes: | Wall Thickness: |

| Height Options: | Standard Sizes: |

| Load Rating: | Installation: Crane ready with liftng hardware |

Delivery & Installation

On average, prestressed seating risers take about 6-8 weeks before they are ready to leave our facility. Our delivery network makes shipping fast and easy! Each project is different and your timeline will be discussed when the order is placed.

Applications & Use Cases

Precast seating risers are widely used in stadiums, arenas, auditoriums, and performing arts venues to create durable, uniform, and precisely aligned tiered seating. Their modular design allows for rapid installation, reducing construction time and labor costs while ensuring long-term performance. Seating risers integrate seamlessly with raker beams and other precast components, making them an efficient solution for projects requiring high capacity, structural precision, and consistent finish quality.

Product Information

Technical Specs

Standard Sizes:

Wall Thickness:

Height Options:

Installation: Crane ready with liftng hardware

Delivery & Installation

On average, prestressed seating risers take about 6-8 weeks before they are ready to leave our facility. Our delivery network makes shipping fast and easy! Each project is different and your timeline will be discussed when the order is placed.

Applications & Use Cases

Precast seating risers are widely used in stadiums, arenas, auditoriums, and performing arts venues to create durable, uniform, and precisely aligned tiered seating. Their modular design allows for rapid installation, reducing construction time and labor costs while ensuring long-term performance. Seating risers integrate seamlessly with raker beams and other precast components, making them an efficient solution for projects requiring high capacity, structural precision, and consistent finish quality.

Our Locations

SAN MARCOS, TEXAS (HEADQUARTERS)

Heldenfels Enterprises, Inc.

5700 IH-35 South. San Marcos, TX 78666

Tel: (512) 396-2376

Fax: (512) 396-2381

CORPUS CHRISTI, TEXAS

Heldenfels Enterprises, Inc.

2222 Laredo St. Corpus Christi, TX 78405

Juan Aguirre: (361) 533-1031

Heldenfels Headquarters

Heldenfels Corpus Christi

Frequently Asked Questions

What are precast concrete seating risers?

Precast seating risers are sloped concrete units that form the stepped platforms for seating in stadiums, arenas, and auditoriums. They provide structural support and define the spectator seating layout.

Where are seating risers typically used?

They’re used in sports venues, performance halls, lecture theaters, and worship centers. You will see these anywhere stepped seating is needed for clear sightlines and efficient space use

How do precast risers help with construction efficiency?

Because they’re fabricated off-site and arrive ready to install, precast risers reduce on-site labor and shorten project schedules, allowing entire seating sections to be set in days rather than weeks.

Can utilities or features be integrated into precast risers?

Yes. Electrical conduits, handrail sleeves, and seating anchor points can be embedded during casting, simplifying later installation of lighting, seats, or safety features.

How durable are precast seating risers?

Precast risers are made with high-strength, dense concrete that resists cracking, impact, and weathering, ensuring long-term performance even in outdoor stadium environments.

Larry Miller, PE

VP of Pre Construction & Business Development

Speak with a Precast Seating Risers Expert Today!

Direct message an experienced Precast Seating Risers expert about your project. We are happy to discuss your project’s goals and expectations.