Introduction: The Dawn of a New Era in Infrastructure Development

The demand for resilient, efficient, and sustainable infrastructure has never been greater. Aging transportation networks, rapid urbanization, and the increasing frequency of extreme weather events are placing immense pressure on traditional construction methods, which often struggle with slow timelines, budget overruns, and significant public disruption. In response, the construction industry is undergoing a paradigm shift, driven by innovations that prioritize speed, quality control, and long-term value. The global precast concrete market is a testament to this shift, expected to grow by USD 21.87 billion between 2023 and 2028. At the forefront of this evolution is a specific, high-performance component: the precast concrete box beam, a structural element that is fundamentally reshaping how we build the arteries of modern society.

Beyond Traditional Construction: Introducing Precast Box Beams

Precast concrete involves casting concrete in a reusable mold or “form” which is then cured in a controlled environment, transported to the construction site, and lifted into place. This off-site manufacturing process is the foundation for a wide array of products, from Precast Walls to Precast Pipes and Manholes. A precast box beam is a specialized structural member with a hollow, rectangular, or trapezoidal cross-section. This unique geometry, combined with the precision of factory production, creates a component that is lighter than a solid beam of similar dimensions yet possesses exceptional strength and rigidity, making it an ideal solution for bridges, elevated roadways, and other critical infrastructure.

Unpacking the Engineering Marvel: What Makes Precast Box Beams Superior?

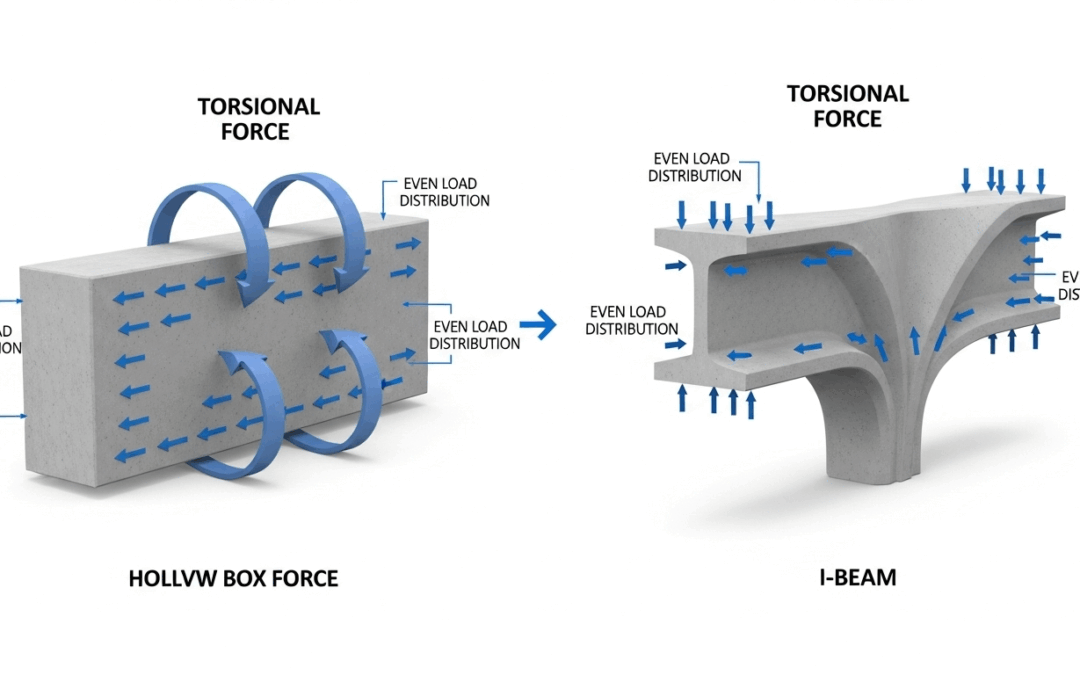

The transformative impact of precast box beams stems from a powerful combination of geometric efficiency and advanced manufacturing. Unlike standard precast beam types, the box shape delivers unique structural advantages that structural engineering professionals leverage to create safer, more durable, and more elegant structures.

The Inherent Structural Advantages of the Box Section

The true genius of the box beam lies in its hollow, four-sided shape. This configuration provides superior torsional rigidity, meaning it is highly resistant to twisting forces. For bridges and elevated highways, where vehicle loads are dynamic and often unevenly distributed, this resistance is critical for maintaining structural stability. The closed section efficiently distributes loads—including bending, shear, and torsion—across its entire profile. This inherent structural integrity allows for the design of longer spans with fewer support piers, leading to more open, aesthetically pleasing designs and reduced foundation costs. The material is used more efficiently, minimizing self-weight while maximizing strength.

The Power of Precasting: Precision, Quality, and Material Optimization

Manufacturing box beams in a controlled factory setting elevates their performance far beyond what is achievable with on-site casting. This process allows for precise control over concrete mixing, placement, and curing, resulting in a product of consistent high quality and strength. Furthermore, it enables the seamless integration of prestressed concrete technology. High-strength steel strands are tensioned within the beam’s form before the concrete is poured. Once the concrete cures, the tension is released, placing the beam under a state of compression. This internal compressive force counteracts the tensile stresses that will be applied by traffic and self-weight, significantly increasing the beam’s load-carrying capacity, preventing cracking, and enhancing its overall durability.

Accelerated Project Delivery: Speed and Efficiency Redefined

In an era where time is a critical resource, the ability to shorten project timelines without compromising quality is a paramount advantage. Precast box beams are central to the principles of Accelerated Bridge Construction (ABC), a modern approach championed by agencies like the Federal Highway Administration.

Modular Construction and Rapid Deployment

Precast box beams function as modular precast units that are manufactured off-site while foundational work, such as the construction of Precast Columns and Piers, proceeds simultaneously on-site. This parallel activity drastically reduces the project’s critical path. Once the site is prepared, the finished beams are transported and can be erected in a matter of days, not weeks or months. This “plug-and-play” methodology minimizes on-site labor requirements and streamlines the entire construction sequence, leading to faster project completion and an earlier return to service for vital transportation corridors.

Minimizing Disruption and Enhancing On-Site Safety

Traditional cast-in-place construction requires extensive on-site formwork, prolonged concrete curing times, and significant space, leading to extended road closures and traffic congestion. The rapid deployment of precast box beams dramatically reduces this public disruption. By shifting the bulk of construction activity to a factory, on-site work is condensed into a much shorter window. This not only benefits the public but also enhances worker safety by minimizing their exposure to live traffic and other on-site hazards. A controlled factory environment is inherently safer than a dynamic, weather-exposed construction site.

Building for Generations: Unrivaled Durability and Longevity

Infrastructure is a long-term investment, and the materials used must be capable of withstanding decades of heavy use and environmental exposure. Precast box beams are engineered for exceptional resilience and a long service life, ensuring the structural stability of critical assets for generations.

Superior Structural Performance and Resilience

The high-quality, densely compacted concrete produced in a factory setting exhibits low permeability, making it highly resistant to water ingress, freeze-thaw cycles, and chemical attacks from de-icing salts. When combined with the crack-resistance offered by prestressed concrete, precast box beams provide a robust barrier against corrosion of the internal steel reinforcement—a primary cause of deterioration in conventional bridges. This superior material performance ensures the structure maintains its design strength and serviceability over its intended lifespan with minimal degradation.

Meeting and Exceeding Modern Standards

State departments of transportation and the Federal Highway Administration (FHWA) have rigorous standards for precast bridge components to ensure public safety and asset longevity. The quality control inherent in precast manufacturing makes it easier to consistently meet and exceed these specifications. The reliability of factory-produced components gives engineers and public agencies confidence in the long-term performance of the structure. This reliability is a key reason why precast solutions are increasingly specified for critical infrastructure projects across the nation.

Economic Advantages and Lifecycle Cost-Effectiveness

While performance and speed are crucial, project viability ultimately depends on sound economics. Precast box beams deliver value not only through initial construction efficiencies but also through significant long-term savings.

Upfront Savings Through Efficiency

The speed of precast construction translates directly into cost savings. Reduced on-site labor hours, shorter equipment rental periods, and decreased financing costs all contribute to a lower initial project price tag. The efficiency of the box section design often requires less overall material compared to solid concrete members, further optimizing the budget. The market reflects this value, with the United States precast concrete market projected to reach USD 36.45 Billion by 2033.

Long-Term Value and Reduced Maintenance

The true economic benefit of precast box beams is realized over the structure’s entire lifecycle. Their enhanced durability and resistance to environmental degradation mean significantly lower maintenance, repair, and rehabilitation costs. A bridge built with precast components will require fewer lane closures for repairs, reducing both direct maintenance expenses and the indirect economic costs associated with traffic delays. This focus on long-term performance makes precast box beams a fiscally responsible choice for public infrastructure investment.

Design Versatility and Multifunctional Applications

Precast box beams offer structural engineers and architects significant design flexibility, enabling them to create structures that are not only functional and durable but also aesthetically pleasing and adaptable to future needs.

Enabling Longer Spans and Aesthetically Pleasing Structures

The high strength-to-weight ratio of prestressed box beams allows for longer, more slender spans. This capability reduces the need for intermediate piers, which can be advantageous when crossing wide rivers, deep valleys, or busy highways. The result is a cleaner, more elegant structure with a reduced environmental footprint. The flat soffit (underside) of adjacent box beam superstructures also presents a clean, uniform appearance that is visually appealing.

Integrated Utility Management and Future-Proofing

The hollow core of a box beam is not wasted space. It provides a protected and easily accessible conduit for utilities such as fiber-optic cables, power lines, and water mains. This integration simplifies utility installation and maintenance, shielding these critical services from weather and physical damage. This inherent functionality helps future-proof infrastructure, allowing for easier upgrades and additions without the need for major structural modifications.

Diverse Applications Across Modern Infrastructure Projects

While most commonly associated with bridges, the principles of precast box beams and other precast components are being applied across a wide spectrum of infrastructure projects.

The Backbone of Modern Bridges and Elevated Roadways

The use of precast box beams as essential precast bridge components is their most prominent application. From short-span rural bridges to complex urban interchanges, they provide a reliable, efficient, and durable solution. The growth in this sector is significant, with the global prefabricated bridges market projected to reach USD 22.8 billion by 2032. Industry leaders like Fort Miller Precast and American Precast have demonstrated how these modular precast units can be deployed to replace aging bridges in a fraction of the time required by traditional methods.

Supporting Critical Transportation Networks

Beyond bridges, Precast Beams and Girders based on box section principles are used in elevated rail lines, airport taxiways, and pedestrian overpasses. Their strength and rapid installation are ideal for projects in congested urban areas where minimizing disruption is critical. The precast ecosystem also includes complementary elements like Precast Slabs for decking and Precast Walls for retaining structures and abutments, creating a total system solution.

Expanding Horizons: Tunnels and Specialized Structures

The versatility of precast concrete extends to other demanding applications. Segmental box sections are used to construct tunnels, providing a safe and efficient method for underground construction. In industrial settings, precast beams support heavy equipment and complex piping systems. The fundamental benefits of factory-controlled quality, speed, and durability make precast a go-to solution for nearly any structural challenge.

The Future is Precast: Innovation, Resilience, and Sustainability

As we look toward the future, the role of precast box beams and other precast components will only grow in importance. They are uniquely positioned to address the pressing challenges of climate change, resource scarcity, and the need for smarter construction practices.

Driving Sustainable Construction Practices

Precast concrete manufacturing is an inherently sustainable process. Factory production minimizes waste, allows for the precise use of materials, and reduces on-site environmental disruption from noise and dust. The industry is also a leader in adopting greener materials; for instance, a 2023 report showed that 82% of UK structural precast manufacturers regularly use Supplementary Cementitious Materials (SCMs) like fly ash or slag to reduce the carbon footprint of the concrete mix. The longevity of precast structures also means a lower lifecycle environmental impact.

Meeting the Demands of Tomorrow’s Infrastructure

The future demands infrastructure that is not only built quickly but built to last. The inherent resilience of precast box beams makes them ideal for creating structures that can withstand more extreme weather events and heavier traffic loads. As the global precast construction market continues its strong growth, poised to reach USD 267.92 billion by 2032, ongoing innovations in materials and design will further enhance the performance and applicability of these essential components, ensuring they remain a cornerstone of infrastructure development.

Conclusion: Paving the Way for a Stronger, Faster Future

The shift towards precast construction is not merely a trend; it is a fundamental transformation in how we approach the development of modern infrastructure. Precast box beams stand at the center of this revolution, offering a solution that is faster, safer, more durable, and more economical than traditional methods.

Recapping the Transformative Impact

From the engineering elegance of the box section’s torsional rigidity to the quality assurance of factory production, precast box beams deliver unparalleled structural integrity and stability. They enable accelerated project delivery, drastically reducing public disruption while enhancing on-site safety. Their superior durability translates into lower lifecycle costs and infrastructure that is built to serve communities for generations, all while supporting more sustainable construction practices.

The Indispensable Role of Precast Box Beams

As we continue to build and rebuild the networks that connect our world, precast box beams have proven themselves to be an indispensable tool. They empower engineers, contractors, and public agencies to meet the immense challenges of the 21st century with confidence. By embracing this technology, we are not just building bridges and roads; we are paving the way for a stronger, more resilient, and more efficient future for all.