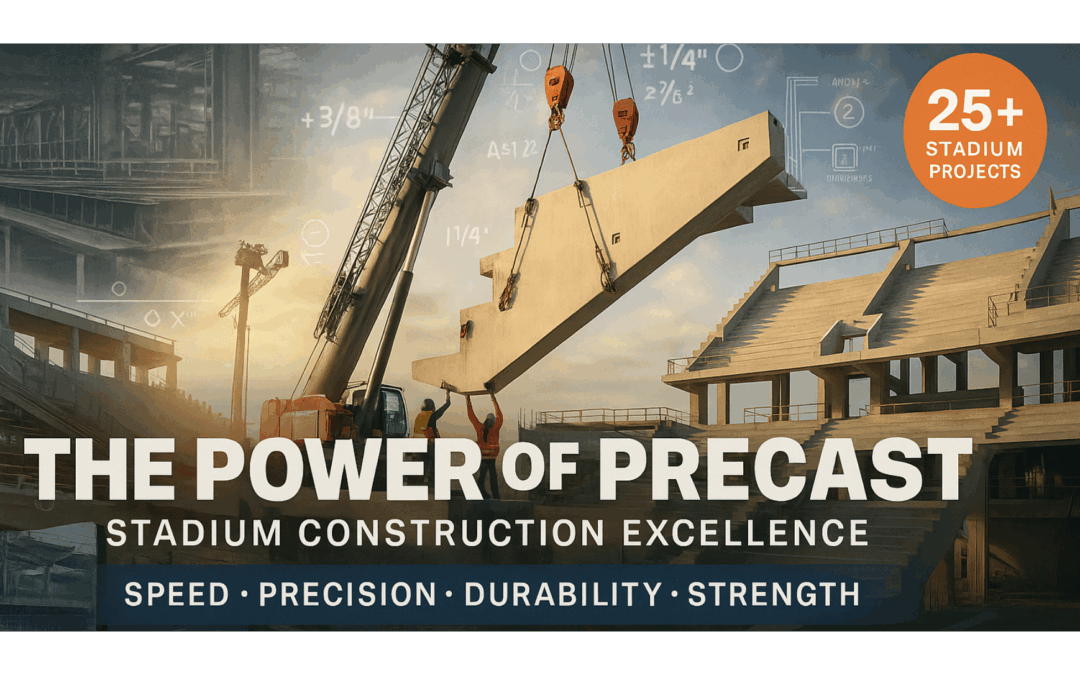

The Power of Precast.

Facilitating a Successful Precast Stadium Project

Precast concrete offers an ideal solution for stadium construction. It checks all the boxes – speed, precision, durability, and aesthetics. In addition, the prestressed components take all the benefits of precast you already get—speed, precision, durability—and add higher strength, longer spans, and slimmer profiles, fewer structural supports, which translates to faster erection schedules, and perhaps fewer raker beams and supports —all while delivering the strength and durability necessary for high-occupancy venues.

However, realizing these benefits requires partnering with a precast producer experienced in stadium work. Every phase—from estimating and engineering to production, delivery, erection, dry-packing, grouting, and punchout—presents its own set of challenges. In construction, unexpected issues inevitably arise, and having a seasoned team like Heldenfels Enterprises, with decades of experience, makes all the difference.

Collaboration During the Design Phase

A successful precast stadium project begins long before the first piece is cast. Early collaboration among the precast producer, architect, structural engineer, and general contractor is essential. Decisions regarding riser layouts, sightlines, vomitory openings, stair configurations, and support framing made during this phase significantly affect constructability, cost-efficiency, and connection detailing.

Unfortunately, precast manufacturers are often brought into the project after design decisions have already been finalized. In such cases, selecting a producer with extensive stadium experience becomes even more critical. Access to structural steel models, embed locations, and MEP penetrations enables early clash detection long before production begins. Precast construction does not happen in isolation; misaligned embeds or uncoordinated penetrations can lead to costly field adjustments. Shared 3D models and digital coordination are indispensable tools for minimizing these risks. A project kickoff meeting and weekly meetings thereafter are crucial for keeping communication channels open.

For deeper technical background on precast design and stadium components, see the Precast/Prestressed Concrete Institute (PCI) technical resources.

Execution Phase: Formwork, Erection, and Logistics

Formwork Drives Quality

Stadium components—such as risers, raker beams, tubs, wall panels, and vomitory walls—often feature complex and repetitive geometries. Investing in high-quality steel formwork is crucial and arguably one of the most impactful early decisions of a stadium project. These structures demand tight tolerances and consistency across hundreds of pieces. Steel forms ensure dimensional accuracy, alignment, finish compatibility, and properly fitted connections.

However, because every stadium is unique, steel formwork is typically project-specific. Adjustable steel forms are not widely available, and the lead time for fabrication is several months for “fixed” form work. If a precast manufacturer is not engaged early, significant form modifications may be necessary—undermining both quality and schedule.

Erection: Where it All Comes Together

Erection is one of the most critical stages in any precast project, especially for stadiums. Even the best-designed and well-fabricated components can be compromised by poor erection planning or execution, leading to delays, safety concerns, rework, or structural failures. Working with a PCI-certified erector—ideally one managed directly by the precast supplier—ensures accountability, quality, and alignment with design intent.

Erection involves complex sequencing, shimming, leveling, welding, and geometry verification across thousands of connections. There are techniques that only experienced crews possess—such as installing risers without cracking, or torquing weld plates without damaging embeds. Having an expert team in place is essential to avoid costly mistakes on the job site.

Logistics and Planning

Effective logistics and planning are vital. Factors like laydown yard placement, shuttle trucks, trailer staging, and direct-to-crane delivery can dramatically affect safety and efficiency. Stadium job sites are often congested, with multiple trades and limited access. A detailed logistics plan minimizes congestion and keeps installation on schedule. Adequate trailer availability also ensures continuous delivery and avoids field downtime.

Explore our work with precast raker beams, Precast risers, and precast walls.

Project Management: The Key to Consistency

An experienced precast project manager is an invaluable asset. Stadium jobs demand constant adaptability—field conditions shift, tolerances are tight, and precision is critical. A knowledgeable PM who understands both the project and the product is your first line of defense against misalignment, rework, or delay. Their on-site presence supports the erection crew and ensures alignment with datum lines, elevation controls, and construction sequencing.

Conclusion

At the heart of every successful stadium precast project lies coordination, communication, and experience. At Heldenfels Enterprises, we’ve completed over 25 stadium projects across Texas and beyond. We understand the intricacies of these complex structures and how to manage them—from early design and modeling through to final punchout. Our team works closely with owners, architects, engineers, and contractors to ensure that every piece fits—structurally, architecturally, and logistically.

Sports & Entertainment Facilities:

- Bowers Stadium, Sam Houston State University – Huntsville, TX

- Mansfield Multipurpose Stadium – Mansfield, TX

- Worthy Fate High School Gymnasium – Dallas, TX

- Salado High School Gymnasium – Salado, TX

- Round Rock Sports Center – Round Rock, TX

- Katy High School Football Stadium – Katy, TX

- Tartleton Convention Center – Tartleton, TX

- The New Football Development Center – University of Houston

- Texas Tech South Endzone Project – Lubbock, TX

- Northwest High School Gymnasium – Forth Worth, TX

- Fort Bend Epicenter – Houston, TX

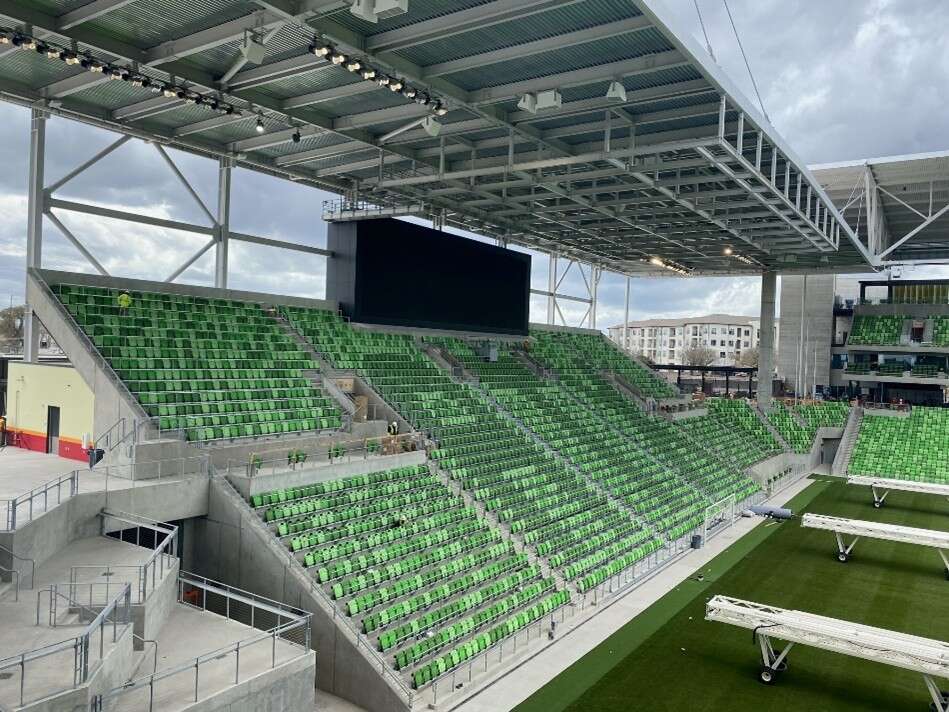

- Austin FC Professional Soccer Stadium – Austin, TX

- Moody Center – Austin, TX

- UT Men’s Basketball Arena – Austin, TX

- Kyle Field Redevelopment, Texas A&M University – College Station, TX

- McLane Stadium, Baylor University – Waco, TX

- AT&T Jones Stadium, Texas Tech, North Endzone Expansion – Lubbock, TX

- Dallas Baptist University Ballpark – Dallas, TX

- Dynamo Stadium – Houston, TX

- Allen Events Center – Allen, TX

- Cedar Park Arena – Cedar Park, TX

- AT&T Stadium, Home of the Dallas Cowboys! – Arlington, TX

- Toyota Center – Houston, TX

- American Bank Center – Corpus Christi, TX

- Whataburger Field – Corpus Christi, TX

- AT&T Center – San Antonio, TX

- NRG Stadium – Houston, TX

- Minute Maid Park – Houston, TX

- Kyle Field, North Endzone Expansion, Texas A&M University – College Station, TX