Introduction: The Foundation of Bridge Design

Bridges are the silent arteries of modern society, connecting communities and facilitating commerce. Yet, the engineering marvels that allow them to withstand immense loads and the test of time often go unnoticed. With 36% of all U.S. bridges—over 222,000 spans—requiring major repair or replacement, understanding their fundamental components has never been more critical. At the heart of many of these structures lies the girder, a powerful support element that serves as a foundational component in countless bridges worldwide.

Why Structural Choices Matter for Infrastructure

The selection of a bridge’s primary support system is one of the most consequential decisions in civil engineering. This choice dictates not only the bridge’s final appearance but also its span capability, load-bearing capacity, construction timeline, and long-term maintenance requirements. A decision made on the drawing board directly impacts public safety, economic efficiency, and the resilience of our infrastructure for decades. As investment grows, with state and local governments awarding $33.5 billion in highway and bridge contracts through early 2025, making informed structural choices is paramount.

What You’ll Learn: A Girder-Centric Approach to Bridge Support

This guide provides a comprehensive comparison between bridge girders and other key support structures. We will begin by deconstructing the girder itself—defining its role, exploring its various types, and understanding how it manages immense forces. From there, we will broaden our scope to examine other major bridge systems, such as trusses, arches, and suspension bridges. By comparing these structures directly, we will illuminate the specific factors—from traffic volume to project budget—that guide engineers in selecting the optimal design for any given challenge.

Understanding Bridge Girders: The Versatile Workhorse of Many Spans

Girders are a cornerstone of modern construction, forming the primary support system for a vast number of bridges and buildings. Their combination of strength, versatility, and relative ease of fabrication makes them an indispensable tool for engineers.

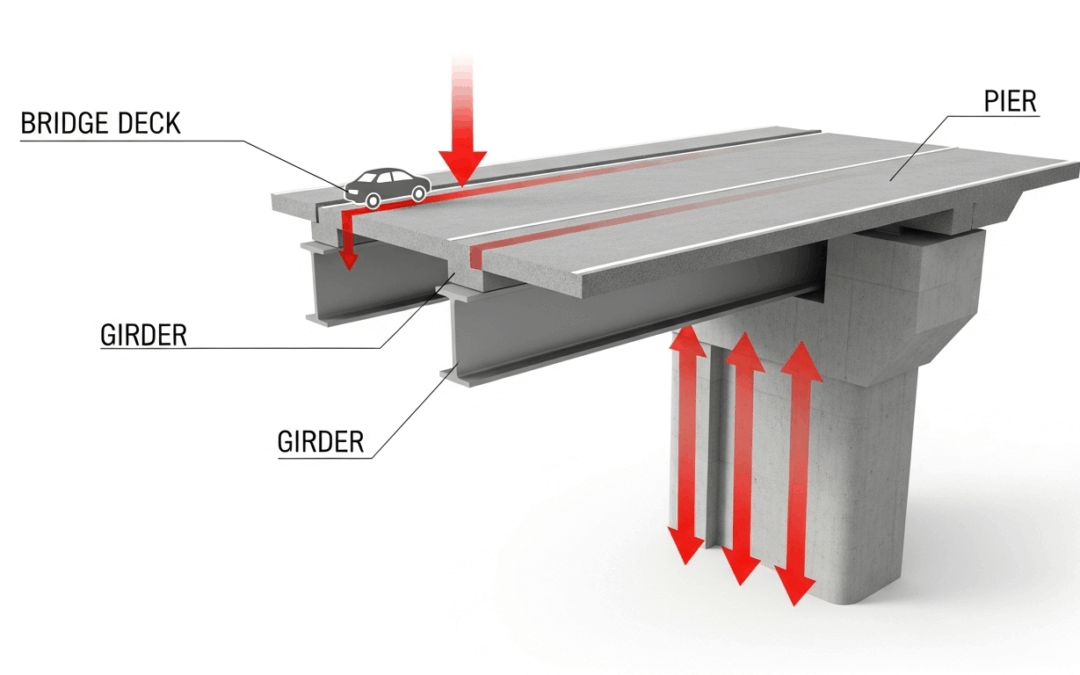

What is a Bridge Girder? Definition and Fundamental Role in Bridge Superstructure

A bridge girder is a large, horizontal structural member that serves as a primary support for the bridge deck—the surface that carries traffic. Essentially a very large beam, a girder is designed to span significant distances between supports, such as piers and abutments. Its fundamental role is to collect the loads from the deck (including the weight of vehicles, pedestrians, and the deck itself) and efficiently transfer these forces to the bridge’s substructure. Girders are the main load-bearing components of the superstructure in many common bridge types.

Key Types of Girders and Their Applications

While all girders serve a similar purpose, their design varies based on the specific needs of the project. The two most common types in bridge construction are:

- I-Beams (or Plate Girders): Named for their “I” or “H” shaped cross-section, these are incredibly efficient at resisting bending forces. The vertical web resists shear forces, while the horizontal flanges resist most of the bending moment. I-beams are fabricated from steel plates and are widely used for short-to-medium span beam bridges due to their excellent strength-to-weight ratio.

- Box Girders: These girders have a hollow, box-like cross-section, typically rectangular or trapezoidal. This design provides superior torsional stiffness, making them highly resistant to twisting forces. Box girders are ideal for curved bridges, longer spans, and situations where aesthetic considerations are important, as they offer a clean, enclosed appearance.

Common Materials for Bridge Girders

The material chosen for a girder is critical to its performance and longevity. The primary materials used include:

- Steel: The most common material for bridge girders, steel offers exceptional tensile and compressive strength, durability, and the ability to be fabricated into precise shapes. Its high strength allows for longer spans and lighter superstructures. The global steel bridge market is a testament to its widespread adoption.

- Prestressed Concrete: Concrete is strong in compression but weak in tension. Prestressed concrete girders overcome this by casting high-strength steel tendons within the concrete, which are then tensioned. This process induces compressive stress that counteracts the tensile forces the girder will experience under load, making it highly efficient and durable.

How Bridge Girders Provide Structural Support

The effectiveness of a girder-based system lies in fundamental engineering principles that allow it to manage and redirect immense forces safely and efficiently.

Principles of Load Distribution and Bearing

When a vehicle crosses a bridge, its weight creates a “live load” on the deck. The deck transfers this load to the nearest girders. The girders, acting as the primary horizontal supports, bend slightly under this load. This action creates compressive forces in the top flange and tensile forces in the bottom flange. The girder channels these forces along its length to the points where it rests on the substructure, effectively distributing a concentrated load over a wider area.

Integration with Bridge Superstructure and Substructure

A girder is not an isolated element; it is part of an integrated system.

- Superstructure: The girders support the bridge deck directly, often connected via shear studs or other fastening systems to create a composite structure that acts as a single unit. This integration enhances the overall strength and stiffness of the span.

- Substructure: At each end of its span, the girder rests on bearings placed atop piers (intermediate supports) or abutments (end supports). These bearings allow for slight movement due to thermal expansion and contraction while transferring the vertical loads from the girder into the foundations and ultimately into the ground.

Advantages of Girder-Based Systems

Girder bridges, particularly beam bridges using I-beams or box girders, are popular for several key reasons:

- Fabrication Efficiency: Girders can be fabricated off-site in controlled factory conditions, ensuring high quality and rapid production.

- Speed of Construction: Once fabricated, girders can be transported to the site and erected relatively quickly, minimizing traffic disruption.

- Scalability: The design is highly scalable. For longer spans, girders can be made deeper; for wider bridges, more girders can be placed side-by-side.

- Cost-Effectiveness: For short-to-medium spans, girder-based systems are often the most economical solution due to their simple design and efficient use of materials.

Exploring Other Major Bridge Support Structures

While girders are foundational, they are just one of many solutions engineers use to span obstacles. Other bridge types rely on different structural principles to achieve strength and stability.

Truss Bridges: Interconnected Strength for Longer Spans

A truss bridge uses a series of interconnected triangular elements to form its superstructure. Instead of a solid girder resisting bending, a truss distributes loads through a network of members that are primarily in tension or compression. This design is highly efficient, using less material to achieve significant strength, making truss bridges an excellent choice for medium-to-long spans where weight is a critical factor.

Arch Bridges: Compressive Power and Classic Aesthetics

Arch bridges are one of the oldest bridge types, transferring the load from the deck into compressive forces along the arch. These forces are then carried into the abutments at either end of the arch. This design is incredibly strong and durable, as materials like stone and concrete are exceptionally resistant to compression. Arches are often chosen for their aesthetic appeal and are suitable for spanning valleys and rivers where solid foundations can be built for the abutments.

Suspension Bridges: Elegance and Grandeur for Very Long Spans

For the longest spans, suspension bridges are unparalleled. Their primary support system consists of massive towers, main suspension cables draped between them, and vertical suspender ropes or cables that hang down to hold up the deck. The bridge deck’s weight is transferred through the vertical suspenders to the main cables, which are in tension, and then to the towers, which channel the forces into the earth. The cables are anchored into massive concrete blocks at each end of the bridge.

Cable-Stayed Bridges: Modern Efficiency for Medium-Long Spans

A cable-stayed bridge is similar to a suspension bridge but differs in how the cables support the deck. Instead of large main cables, a series of individual cables extend directly from the towers to the bridge deck at various points. This creates a distinctive fan-like or harp-like pattern. Cable-stayed bridges are structurally efficient for medium-to-long spans and are often seen as a modern, aesthetically striking alternative to other bridge types.

Cantilever Bridges: Projecting Support for Complex Geographies

A cantilever bridge is built using cantilevers—structures that project horizontally into space, supported on only one end. For a bridge, two cantilevers often project from opposite piers, meeting in the middle or supporting a simple suspended span between them. This design is useful where temporary supports during construction are difficult to place, such as over deep gorges or busy waterways.

Direct Comparison: Bridge Girders vs. Other Support Structures

Choosing the right structural system involves a trade-off between span, cost, material, and complexity.

Span Capacity and Load-Bearing Capabilities

- Girders (Beam Bridges): Excellent for short-to-medium spans (up to ~200 feet). Load capacity is high but becomes inefficient over very long distances as the girder’s own weight becomes a major factor.

- Trusses: Effective for medium-to-long spans (200-1,000+ feet), offering a better strength-to-weight ratio than solid girders for these distances.

- Arches: Best suited for medium spans, with capacity heavily dependent on the ground conditions at the abutments.

- Cable-Stayed/Suspension: Unmatched for long to very long spans (1,000-7,000+ feet). Their design efficiently transfers loads over vast distances, making them the only option for major water crossings.

Material Selection and Structural Efficiency

- Girders: Primarily use steel and prestressed concrete. They are materially efficient for shorter spans but less so for longer ones.

- Trusses: Highly efficient use of steel, as the members are arranged to handle pure tension or compression, maximizing the material’s strength.

- Arches: Traditionally used masonry and concrete, leveraging their high compressive strength.

- Cable-Stayed/Suspension: Rely on high-strength steel for their cables, which is the most efficient way to handle tensile forces over long distances.

Construction Complexity, Fabrication, and Timeline

- Girders: Simple and fast to fabricate and erect, making them ideal for projects with tight schedules.

- Trusses: More complex to fabricate due to the large number of individual members and connections, which can extend construction time.

- Arches: Construction can be complex, often requiring extensive falsework (temporary support) until the arch is complete and self-supporting.

- Cable-Stayed/Suspension: The most complex and time-consuming to build, involving intricate cable erection and balancing of forces.

Aesthetic Considerations and Environmental Integration

Each bridge type offers a distinct visual profile. Girder bridges provide a simple, clean, and unobtrusive look. Arches offer a classic, powerful aesthetic. Trusses present an intricate, industrial feel. Suspension and cable-stayed bridges are often chosen for landmark projects, creating dramatic and elegant silhouettes that define a city’s skyline.

Factors Influencing the Choice: When to Opt for Girders or Alternatives

The final decision on a bridge’s design is a complex equation solved by structural engineers, balancing numerous competing factors.

Project Span Length and Geometry Requirements

The required distance to be crossed is the single most important factor. Girders are the default choice for short spans, while cable-supported systems become necessary for very long spans. The geometry, such as a curved alignment, might favor a box girder system due to its torsional strength.

Expected Load Requirements and Traffic Volume

The bridge must be designed to safely handle the maximum expected load, including the weight of heavy trucks and high traffic volumes. While all bridge types are designed for safety, certain systems, like robust concrete girders, are well-suited for heavy, high-volume freight routes.

Site Conditions, Geotechnical Considerations, and Foundation Constraints

A soil report revealing poor ground conditions might preclude an arch bridge, which requires extremely stable ground to handle the arch’s thrust. Similarly, deep water or a difficult-to-access ravine might make a cantilever or cable-stayed design more practical than a girder bridge requiring multiple piers.

Budget, Schedule, and Comprehensive Lifecycle Costs

Cost is a major driver. While the initial construction cost is significant—and rising, with highway construction costs up 336 percent since 2003—it’s not the only consideration. Lifecycle costs, including inspections and maintenance, are also critical. Simple girder bridges often have lower long-term maintenance costs than complex truss or cable systems.

Environmental Impact, Sustainability Goals, and Material Selection

The environmental impact of construction, including material sourcing and disruption to the site, is an increasingly important factor. The choice between steel and concrete can be influenced by local availability, recycled content, and the carbon footprint associated with each material.

Local Expertise, Fabrication Capabilities, and Available Technology

The final choice may also depend on practical considerations. The availability of local steel fabrication shops, experienced construction crews for a specific bridge type, and specialized erection equipment can make one design more feasible and cost-effective than another in a particular region.

Conclusion

The world of bridge engineering is a testament to human ingenuity, where fundamental components like girders are just the beginning of a much larger story. While the girder serves as the versatile and reliable workhorse for a majority of the world’s spans, it operates within a sophisticated ecosystem of supports, including piers, abutments, and foundations. Understanding the distinction between a girder-based system and alternatives like trusses, arches, and cable-stayed bridges reveals a core principle of engineering: there is no universal solution, only the optimal choice for a specific set of challenges.

As we look to rebuild and expand our critical infrastructure, a task underscored by the fact that over 221,000 bridges in the US need significant work, the decision-making process becomes ever more vital. The choice is a complex balance of span, load, geology, budget, and aesthetics. By appreciating the unique strengths of each structural system—from the simple efficiency of a steel I-beam to the breathtaking elegance of a suspension bridge—we gain a deeper understanding of the hidden frameworks that support our modern world. The right choice ensures not just a safe crossing, but a durable, efficient, and lasting piece of public infrastructure.