Introduction: Meeting the Demands of Modern Infrastructure

Modern infrastructure demands are pushing the boundaries of construction, requiring projects to be completed faster, safer, and with greater long-term durability than ever before. In the critical sectors of bridge and marine development, these pressures are amplified by complex logistics, challenging environmental conditions, and the non-negotiable need for structural integrity. Traditional construction methods, while proven, often struggle to meet these escalating expectations, leading to project delays, budget overruns, and quality control issues. This evolving landscape has created a clear need for innovative solutions that can streamline processes without compromising performance.

The Critical Role of Bridges and Marine Structures

Bridges and marine structures are the lifelines of modern economies. They connect communities, facilitate trade, and enable transportation across challenging terrains and waterways. From sprawling highway interchanges to robust port facilities, this infrastructure is fundamental to societal function. The structural performance and longevity of these assets are paramount, as their failure can have catastrophic economic and social consequences.

Challenges in Traditional Infrastructure Development

Conventional cast-in-place construction, where concrete is poured and cured on-site, has long been the standard. However, this method is fraught with challenges. It is highly dependent on weather conditions, susceptible to on-site labor inconsistencies, and requires extensive and costly formwork and shoring. These factors introduce significant variables that can compromise both the project timeline and the final quality of the structure, particularly for critical components like foundation caps.

Introducing Precast Concrete Caps as a Game Changer

In response to these challenges, the precast concrete industry has introduced a transformative solution: precast concrete caps. By manufacturing these critical substructure components in a controlled, off-site environment, precast caps address the core weaknesses of traditional methods. They offer a pathway to accelerated construction, superior quality, enhanced durability, and improved safety, fundamentally changing how complex bridge and marine construction projects are executed.

Understanding Precast Concrete Caps

To appreciate their impact, it is essential to understand what precast concrete caps are and the principles behind their production. They are not merely an alternative material but represent a paradigm shift in construction philosophy.

Defining Precast Concrete Caps

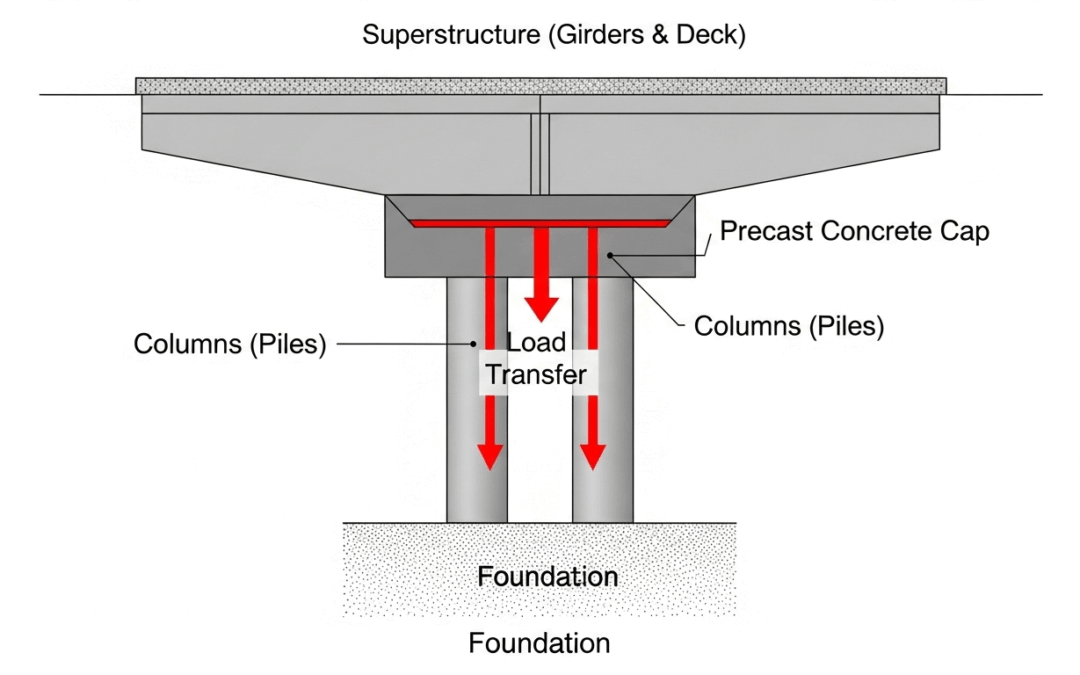

A precast concrete cap, often referred to as a pier cap or a precast bent cap, is a structural member that sits atop columns or piles. Its primary function is to transfer loads from the bridge’s superstructure—the girders and deck—down into the foundation. By creating a stable platform, it evenly distributes immense forces, ensuring the stability and integrity of the entire bridge or marine structure. Precasting involves fabricating these caps off-site before transporting them for installation.

Core Principles of Precast Construction

Precast construction operates on the principle of moving a significant portion of the building process from the unpredictable field environment to a controlled factory setting. This allows for standardized processes, meticulous quality control, and parallel construction paths—the foundation can be prepared on-site while precast members are simultaneously being manufactured. This industrial approach ensures precision, consistency, and efficiency that is difficult to replicate with on-site methods.

The Transformative Advantages of Precast Concrete Caps

The adoption of precast concrete caps is driven by a host of tangible benefits that address the most pressing concerns in modern infrastructure development. These advantages span efficiency, performance, safety, and overall project value.

Enhanced Construction Efficiency and Speed

The most immediate benefit of precast caps is a dramatic acceleration of project timelines. On-site activities are streamlined, as the need for complex formwork, on-site rebar placement, and lengthy concrete curing times is eliminated. Crews can erect precast caps quickly, often in a matter of hours or days instead of weeks, allowing subsequent construction of the superstructure to begin almost immediately. This minimizes disruption to traffic on highways and reduces the overall construction footprint.

Superior Durability and Structural Performance

Manufacturing in a controlled environment allows for the production of high-strength, high-performance concrete with unparalleled consistency. The precise placement of reinforcing steel (rebar) and adherence to strict curing protocols result in a product with superior density and reduced permeability. This enhances its durability and resistance to common deteriorating factors like freeze-thaw cycles and chemical intrusion, ensuring exceptional long-term structural performance.

Improved Safety and Quality Control

Shifting cap construction to a precast facility significantly improves worksite safety. It reduces the amount of labor required at heights and minimizes on-site congestion associated with material staging and formwork. Furthermore, the factory setting enables rigorous quality assurance at every stage of production, from concrete mixing to final finishing. This stringent oversight ensures that every precast bent cap meets exact engineering specifications before it ever reaches the job site.

Resilience Against Seismic and Environmental Forces

Precast concrete caps can be specifically engineered for high performance in challenging conditions. For structures in earthquake-prone regions, connections between precast members can be designed to provide ductility and dissipate seismic energy, enhancing the overall resilience of the bridge. The inherent mass and strength of precast concrete also provide robust resistance to environmental forces such as vessel collisions, high winds, and hydrodynamic loads in marine settings.

Economic and Environmental Benefits

While precast components may have a higher initial material cost, they often lead to significant overall project savings. Reduced labor requirements, shorter equipment rental periods, and minimized weather delays contribute to a lower total installed cost. Environmentally, the precast manufacturing process generates less on-site waste, and the reduced construction duration leads to lower emissions from machinery and traffic detours. The growing adoption of this technology is reflected in market trends, as the global precast concrete market is projected to reach USD 156.13 billion by 2030.

Precast Concrete Caps in Bridge Infrastructure

In bridge construction, precast caps are a cornerstone of accelerated bridge construction (ABC) techniques, offering solutions that reinforce the most critical parts of the structure while accommodating complex designs.

Reinforcing Bridge Substructures

The substructure is the backbone of any bridge. Precast pier caps provide a robust connection point between the columns and the girders, ensuring the stable transfer of vertical and lateral loads into the foundation. Their high quality and uniform strength contribute directly to the safety and longevity of the bridge, forming a reliable base for decades of service on busy highways and crossings.

Addressing Complex Geometries and Span Requirements

Modern bridge designs often feature complex geometries, including curved alignments, variable spans, and significant skews. Precast manufacturing allows for the creation of custom-shaped caps that meet these precise design requirements with high accuracy. This versatility gives engineers greater freedom to design efficient and aesthetically pleasing structures without being constrained by the limitations of on-site forming.

Case Studies and Regulatory Support

Departments of Transportation across the country are increasingly embracing precast solutions. In a state with vast infrastructure needs like Texas, the use of precast bent caps has been instrumental in accelerating highway expansion projects, reducing traffic impacts, and ensuring high-quality outcomes. The Texas DOT has developed standards and specifications that facilitate the use of precast members, demonstrating institutional confidence in their performance and efficiency. This regulatory support is crucial for wider adoption within the precast concrete industry.

Precast Concrete Caps in Marine Infrastructure

Marine environments present some of the most formidable challenges for construction materials. Precast concrete caps offer a durable and efficient solution for building resilient structures in these corrosive and dynamic settings.

Overcoming Harsh Marine Environments

Saltwater, constant moisture, and chemical exposure create a highly corrosive environment that can rapidly degrade traditional construction materials. The dense, low-permeability concrete used in precast manufacturing provides superior resistance to chloride ion penetration, significantly slowing corrosion of the internal rebar and extending the service life of marine structures.

Protecting Pile Bents and Pier Foundations

In piers, jetties, and wharves, precast caps serve as a protective and load-distributing element for the pile foundation. They tie individual piles together into a unified bent, creating a stable substructure capable of withstanding lateral forces from waves, currents, and vessel berthing. This integrated system is essential for the long-term stability of the entire marine facility.

Accelerated Construction for Coastal Projects

Coastal construction windows are often limited by tides, weather, and environmental regulations. Precast caps allow contractors to maximize these windows. By having components ready for immediate installation, crews can rapidly assemble pier bents and foundations, minimizing in-water work and reducing the project’s environmental impact. This speed is critical in a sector seeing massive investment, with major maritime construction projects breaking ground at a cost of roughly $61.6bn in 2023.

Applications in Docks, Piers, and Seawalls

The versatility of precast caps makes them suitable for a wide range of marine applications. They form the foundational structure for loading docks and fishing piers, provide the capstone for sheet pile seawalls, and serve as the base for mooring dolphins and other port infrastructure. In each case, they deliver a combination of structural strength, durability, and construction speed.

Design, Manufacturing, and Installation of Precast Caps

The success of a precast concrete cap lies in a seamless, three-phase process that integrates advanced engineering, precision manufacturing, and efficient on-site logistics.

Advanced Design and Engineering

The process begins with detailed engineering and design. Using advanced modeling software, engineers design the cap to meet specific load requirements, geometric constraints, and connection details. This phase includes precise calculations for the rebar cage design, concrete mix specifications, and lifting points to ensure structural integrity throughout its lifecycle, from fabrication to final installation.

Manufacturing in a Controlled Casting Yard

At the manufacturing plant, the designed rebar cage is assembled and placed into high-quality, reusable steel forms. High-performance concrete is then poured under controlled conditions, ensuring proper consolidation and eliminating voids. The cap is cured in a monitored environment to achieve its specified strength before being stripped from the form and finished, ready for transport.

Efficient Transportation and Erection

Once cured and approved, the precast caps are transported to the construction site. Using heavy cranes, the caps are lifted and precisely set onto the prepared columns or piles. Connections are then made, typically using high-strength grout, cast-in-place closure pours, or specialized mechanical couplers, to create a monolithic and durable final structure.

The Future of Infrastructure with Precast Concrete Caps

As the need for resilient and efficient infrastructure continues to grow, the role of precast concrete caps is set to expand. Ongoing innovation promises to unlock even greater potential for this transformative technology.

Continued Innovation and Research

The precast concrete industry is continually investing in research and development. This includes advancements in ultra-high-performance concrete (UHPC), non-corrosive reinforcing materials, and the integration of smart sensors to monitor structural health. These innovations will further enhance the durability and performance of precast members.

Expanding Applications

While already established in bridge and marine construction, the principles of precast caps are being adapted for other applications. These include building foundations, complex industrial structures, and even large-scale architectural elements. As the benefits become more widely recognized, precast solutions will become an increasingly integral part of diverse construction projects, driving growth in a sector valued at over $21.7 billion in the US alone.

Conclusion

Precast concrete caps represent a fundamental advancement in the development of bridge and marine infrastructure. By moving critical construction processes off-site into a controlled manufacturing environment, they deliver unparalleled benefits in efficiency, quality, and safety. The ability to accelerate project timelines while simultaneously enhancing structural performance and long-term durability makes them an indispensable tool for modern construction. For engineers, contractors, and project owners facing the dual pressures of tight schedules and high performance standards, precast caps offer a proven, reliable, and forward-thinking solution. By embracing this technology, we can build the robust, resilient, and sustainable infrastructure required to support communities and economies for generations to come.