Quick Summary

Dock pilings — the silent stalwarts of maritime infrastructure. The question “how are dock pilings installed?” is more than a straightforward inquiry; it’s the gateway to understanding the robustness of our coastal structures. Engineers and contractors know that proper dock piling installation is crucial when considering the structural integrity of any marine construction project, whether for bustling ports or serene municipal expansions.

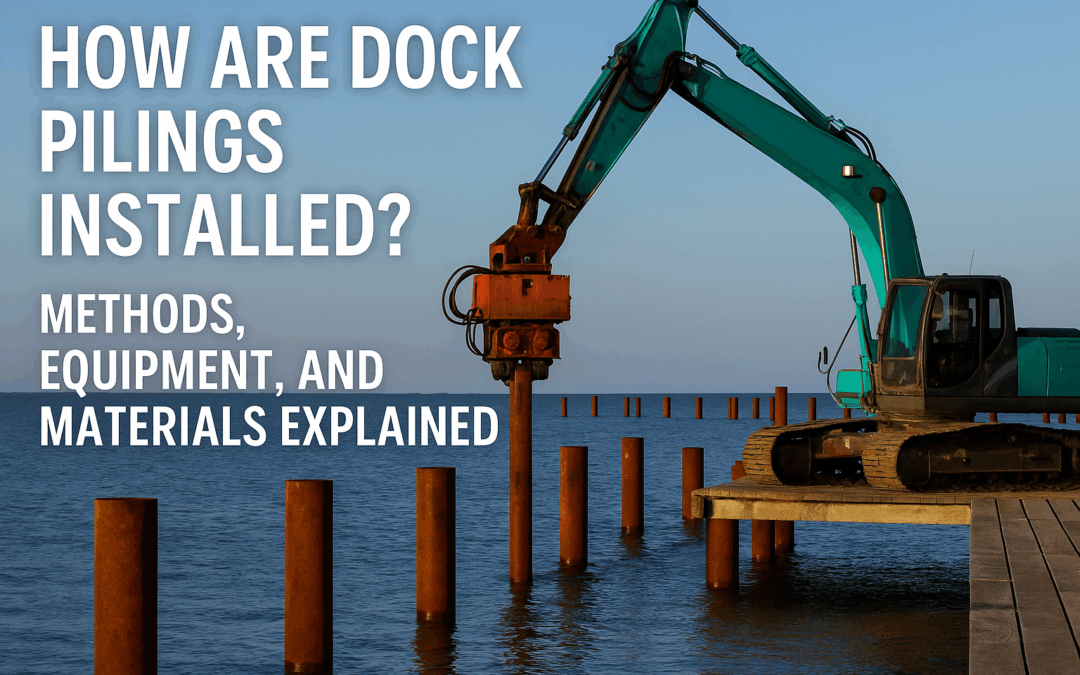

Imagine this: You’re at a coastal LNG offloading terminal, where the sea breeze carries a hint of salt and unpredictability with it, much like every unexpected tantrum thrown by temperamental coastal weather patterns. The installation of dock pilings here requires meticulous planning, formidable equipment, and suitable materials, like precast concrete pilings, to ensure longevity in harsh marine environments. From jetting techniques to the thunderous rhythm of pile drivers, each method has its unique dance with Mother Nature, and each project has its mantra—robust and reliable.

In this blog, aimed at marine contractors, project engineers, and port infrastructure planners, we delve into the mechanical symphony involved in dock and wharf construction. We’ll walk you through the modern methods and heavy-duty equipment employed in installation, explore environmental considerations, and spotlight the role of durable materials and maintenance strategies. Welcome to the intricately fascinating world of dock piling installations.

Importance of Proper Dock Piling Installation

The importance of proper dock piling installation cannot be overstated, as it forms the backbone of safe and durable marine structures. Incorrect installation can lead to premature deterioration, wobbling docks, and costly repairs—hardly what one dreams of when gazing upon a new wharf. Imagine trying to explain to a client that their multi-million-dollar ferry terminal is taking an unexpected tour of the bay!

Key reasons for precision in dock piling installation:

- Longevity: Proper installation ensures that pilings withstand the rigors of saltwater immersion and resist marine degradation.

- Stability: Correctly aligned pilings provide the necessary support for high-load applications, such as industrial shipyards and coastal LNG offloading terminals.

- Safety: Reliable piling installations mitigate the risks posed by natural elements like rocky bottoms and fluctuating water levels.

Here’s a quick comparison of piling materials to consider:

|

Material |

Durability |

Typical Use |

|---|---|---|

|

Precast Concrete |

Excellent |

Ports, Heavy Load Applications |

|

Timber |

Moderately Durable |

Lakes and Lesser Load Areas |

|

Steel |

Highly Durable |

Industrial Shipyards |

For a comprehensive solution to your piling needs, consider Heldenfels’ precast pilings here. For expert insights on marine durability standards, the U.S. Army Corps of Engineers offers valuable guidelines.

Common Methods for Installing Dock Pilings

When contemplating how dock pilings are installed, it’s essential to understand the diverse methods that cater to different environmental conditions and structural requirements. Each technique offers unique advantages, dictated by factors such as soil composition, water depth, and the intended load capacity of the marine structure. The three primary methods include jetting, hammering, and drilling. These methods employ various technologies and equipment to ensure that pilings anchor securely into the underwater substrate. It’s incumbent upon project engineers and marine contractors to choose the most suitable method, balancing between efficiency, environmental impact, and structural integrity.

Jetting Technique

The jetting technique capitalizes on the erosive power of high-pressure water streams to facilitate piling installation. By directing a concentrated stream of water into the sediment, workers create space in the seabed to accommodate the piling. This method is particularly advantageous when dealing with loose, sandy soils, often encountered in coastal regions. Though the technique is efficient and less disruptive than others, precision is paramount to prevent undermining the surrounding substrate. As seasoned contractors will attest, the only thing more unpredictable than coastal weather is the behavior of sand when it’s under pressure.

Jetting is particularly useful for lighter loads and smaller docks, where minimal disturbance is an advantage. However, it’s crucial that operators maintain control over the water pressure and monitor sediment dislocation to ensure the surrounding environment maintains its stability. Despite its ease of use, the jetting technique demands careful planning and execution to avoid collapse or misalignment of the piling structure. In this regard, project managers must employ adept technicians equipped with the latest jetting technology to ensure a successful installation.

Hammering Method

The hammering method, often known as the impact driving method, is a robust solution ideal for driving the pilings deep into denser soil formations. Using a heavy-duty pile driver, this technique involves striking the piling with a powerful hammer to embed it firmly into the ground. While it may lack the grace of a water-based method, the hammering approach delivers sheer force capable of tackling a rocky seabed.

The key advantage of this method is its applicability in handling heavy-duty structures, such as those required for industrial shipyards and coastal LNG terminals. The strong impacts generated allow the pilings to penetrate even challenging substrates, providing reliable stability for high-load applications. However, it is noteworthy that employing this method in heavily populated or environmentally sensitive areas can lead to project delays due to noise regulations and potential impacts on local marine life. Thus, noise-dampening technologies and environmental assessments are vital aspects of modern hammering operations.

Drilling Approach

In scenarios where standard techniques encounter excessive resistance or when precision placement is non-negotiable, the drilling approach becomes invaluable. This method involves the use of rotary equipment to bore a hole into the substrate, allowing for the precise placement of pilings. Once drilled, the hole is filled with a piling, often accompanied by injected concrete or other stabilizing materials. An engineer’s best friend in rocky waters, this approach ensures the longevity and reliability of critical infrastructures, such as ferry terminals and municipal marine expansions.

The drilling approach guarantees alignment accuracy and allows for deeper penetration, critical in high-load environments. It is particularly effective in areas where the ground is rocky or features layers of resistant clay. Although typically more time-consuming than other methods, the precision of a drilled installation enhances structural integrity, minimizing the risk of misalignment or instability. For public works contractors striving for top-tier results, leveraging advanced drills and real-time monitoring systems will ensure a successful implementation of the drilling methodology.

Choosing the optimal method for dock piling installation requires an assessment of environmental conditions and project requirements. Each technique serves a distinct purpose and showcases unique advantages essential for constructing enduring marine infrastructure.

Choosing the Right Method for Environmental Conditions

Selecting the appropriate piling installation method is crucial for achieving a successful dock structure that withstands environmental forces. Different environments—be it bustling industrial shipyards, serene ferry terminals, or rugged coastal LNG offloading stations—demand tailored approaches. The joys of dealing with unpredictable coastal weather can only be overcome by understanding these conditions and their impact on piling methods.

- Environmental Factors

-

- Saltwater Conditions: Precast concrete pilings provide superior durability and corrosion resistance, catering to harsh marine environments.

- Soil and Rock Composition: Vibratory hammers are ideal for sandy soils, while impact hammers deliver excellent results in denser materials.

- Water Depth and Load: Jetting can be applied in shallow waters, while high-load environments demand the strength of impact methods.

- Comparison of Methods and Materials

| Piling Material | Method | Typical Environment |

|---|---|---|

|

Precast Concrete |

Impact |

Saltwater, high-load |

|

Timber |

Vibratory |

Calm waters, low-load |

|

Steel |

Jetting |

Deep waters |

In the unpredictable world of marine pile driving, choosing the right method is your anchor against the whims of nature.

Essential Equipment for Dock Piling Installation

Embarking on a dock piling installation project requires meticulous planning and the right arsenal of equipment. The successful implementation of piling in marine environments is contingent not only on comprehensive engineering designs but also on the specific tools and machinery utilized. From the vast equipment range at your disposal, the tools you select will be influenced by variables like site conditions, water depth, and environmental impacts. Achieving durability and structural integrity in marine dock installations is paramount, and doing so mandates reliance on heavy-duty equipment crafted for such challenging endeavors. Below, we delve into the indispensable tools integral to marine piling projects.

Jetting Tools and Pumps

Jetting tools and pumps play a pivotal role, especially when working in soft or sandy underwater soils. These tools employ high-pressure water to erode and displace the soil, easing the path for pile penetration. The effectiveness of jetting largely depends on the site’s soil composition and the ability to manage turbidity and sediment dispersion. Unlike other methods, jetting offers a less intrusive approach, creating a streamlined process to install pilings without the deafening clang of heavy machinery—though, be sure to keep that garden hose handy for unexpected overflow engagements.

While jetting is a reliable technique for lighter loads and softer terrains, its application is somewhat limited in conditions demanding higher structural strength. It’s generally not feasible on rocky bottoms where stronger force is needed to drive pilings. Instead, jetting serves as a strategic option, especially in enduring shallow-tide waters and installations requiring a gentle yet effective technique. However, it’s important to remember safety guidelines and environmental regulations when applying this method to prevent any unintended ecological damage.

Pile Drivers

Pile drivers form the backbone of marine infrastructure projects, providing the muscle needed to embed piles deep into marine beds. The choice between vibratory and impact pile drivers hinges on site-specific conditions. For instance, vibratory hammers are often utilized in softer substrates, offering a less disruptive approach. Conversely, impact hammers are designed to tackle denser soils and are adept at driving piles through tough materials with decisive force.

Impact drivers are generally preferred for high-load applications found in industrial shipyards or ports due to their robust force, ensuring that precast concrete pilings secure firmly into the seabed. The sheer power of pile drivers makes them indispensable for projects needing enhanced structural integrity—a non-negotiable in environments subjected to aggressive marine degradation or the relentless pull of Tampa Bay waves. Taming the mighty pile driver can admittedly be a test, sometimes requiring weather reports as much as engineering plans—the joys of synchronization amidst coastal gusts.

Drilling Equipment

Drilling equipment becomes essential when conditions are too challenging for standard driving methods, often in terrains featuring hard rock layers. By pre-drilling, contractors can ease the path of pile insertion, especially when building docks or wharf extensions in environments characterized by hardened substrates. Drilling provides precision, cutting through mixed compositions to prepare the ground for the arrival of the pile driver.

Incorporating drilling equipment can be particularly useful in sites where installation requires bypassing existing infrastructure or dealing with various interference like black plastic sleeves or chemical treatments used in previous installations. Opting for drilling equipment paves the way for effective pile placements, minimizing disruption and ensuring that installations are neither compromised by hostile underwater conditions nor the surprise factor of unexpected subsurface discoveries. In essence, drilling forms the bridge where engineering meets execution, transforming that rocky shoreline into a robust docking solution.

Materials Used in Dock Pilings

Dock construction is a complex process that relies on various materials, each selected for specific structural and environmental requirements. The materials used for dock pilings must withstand maritime conditions, including saltwater corrosion, tidal changes, and heavy-load applications. The choice of materials greatly impacts the longevity and durability of marine structures. Engineers typically choose pilings from materials such as treated wood, Greenheart wood, and fiberglass, each offering distinct advantages and drawbacks. The selection hinges on factors such as load-bearing capacity, resistance to environmental degradation, and cost-effectiveness, among others.

Treated Wood Pilings

Treated wood pilings are a timeless choice in marine construction, celebrated for their natural resilience and ease of installation. These pilings are typically pressure-treated with chemical preservatives to enhance their durability against rot, insect infestation, and marine borers. Although treated wood pilings are a cost-effective solution, they require periodic maintenance. Due to their susceptibility to marine degradation, particularly under UV rays and salt-water immersion, regular inspections and potential treatments are necessary to maintain their structural integrity. Despite these challenges, treated wood remains popular, particularly in residential docks and smaller-scale marine projects.

Greenheart Wood Pilings

Greenheart wood pilings represent a more robust alternative to traditional treated wood options. Esteemed for their exceptional strength and natural resistance to marine environments, Greenheart wood pilings offer an eco-friendly solution with minimal chemical treatment. This tropical hardwood, hailing primarily from the forests of South America, showcases unparalleled density and durability. Ideal for high-load applications and hostile conditions, Greenheart is often the material of choice for municipal expansions, ferry terminals, and industrial shipyards. While its toughness is a notable advantage, engineers should account for its higher cost and sourcing challenges, as these factors can impact project budgets and timelines.

Fiberglass Pilings

Fiberglass pilings stand out as a contemporary solution in marine infrastructure, offering a unique mix of strength and longevity. They are particularly lauded for their resistance to the harsh chemical and biological factors prevalent in saltwater environments. Fiberglass pilings are immune to the detrimental effects of UV rays and marine borers, making them a low-maintenance alternative to wood and metal options. Their lightweight nature simplifies transportation and installation, reducing both labor and time costs. Due to these attributes, fiberglass pilings are increasingly popular for modern dock installations, including coastal LNG offloading terminals and other high-tech maritime facilities. While they offer numerous advantages, considerations regarding initial costs and load capacity adjustments are crucial factors for engineers.

Pouring Concrete Pilings

Pouring concrete pilings is a critical phase in constructing robust dock structures. This process involves a detailed set of procedures designed to deliver structural stability and long-term durability, especially in challenging coastal environments. Whether supporting a bustling industrial shipyard or a ferry terminal, precast concrete pilings are the backbone of modern marine infrastructure. In this guide, we will walk through the integral steps of preparing the site, mixing and pouring concrete, and ensuring the pilings provide enduring stability.

Preparing the Site and Forms

Before concrete can be poured, proper preparation of the site and forms is essential. This step ensures that the foundation is ready to support the heavy loads anticipated in maritime construction projects. The area where pilings will be installed must be thoroughly surveyed, with soil testing conducted to assess bearing capacity and identify potential geotechnical challenges. Once the site is prepared, formwork, usually made from durable materials like steel or treated wood, is erected to shape the concrete and hold it in place during the curing process.

Meticulous form preparation not only dictates the shape and size of the pilings but also prevents concrete spillage, ensuring that every drop contributes to constructing a sturdy pile. These forms must be precisely aligned and secured, as any shift can compromise the structural integrity of the completed piling. Additionally, in coastal areas, careful planning is required to address issues like salt-water immersion and marine degradation.

Mixing and Pouring Concrete

With forms in place, the process of mixing and pouring concrete can begin. Concrete used for marine pilings is typically mixed on-site to ensure it meets the specific requirements dictated by environmental conditions and engineering specifications. Often, this involves a mix rich in cement, designed to improve strength and durability.

When pouring the concrete, it’s crucial to maintain a steady flow to avoid air pockets, which could cause weaknesses in the final structure. Pouring is typically done in a continuous manner, minimizing cold joints and ensuring uniformity throughout the piling. For large-scale projects like those at ports or LNG terminals, advanced equipment such as rotary drum mixers and pumps are employed to move large volumes of concrete efficiently.

Ensuring Stability and Longevity

Ensuring the stability and longevity of concrete pilings demands attention to detail and an understanding of the unique environmental stresses they will face. One key factor is the curing process, which allows the concrete to reach its desired strength. Proper curing methods might include keeping the concrete moist for a set period, protecting it from extreme temperatures, and shielding it from the fluctuating tides that characterize many marine settings.

Additionally, incorporating corrosion-resistant materials like stainless steel reinforcing bars can help combat the corrosive effects of saltwater. These measures, coupled with regular inspection and maintenance schedules, help ensure that the concrete pilings continue to perform under high-load applications.

In summary, pouring concrete pilings is a sophisticated process that requires precise coordination and expertise, particularly for projects in challenging coastal conditions. By carefully preparing the site, mixing and pouring concrete with attention to detail, and ensuring the finished product’s long-term stability, marine contractors can create durable structures. For those looking to implement such dependable infrastructure, turning to trusted providers like Heldenfels for precast pilings is pivotal in achieving success. For further reading on piling design and marine durability standards, insights from the U.S. Army Corps of Engineers provide valuable guidance.

Rot Prevention and Maintenance

Effective rot prevention and maintenance are crucial for extending the lifespan of structures vulnerable to moisture and decay. Whether you’re overseeing marine infrastructure or wooden residential buildings, safeguarding materials from rot can prove to be a significant challenge. This involves a blend of selecting the right materials, implementing protective measures, and adhering to rigorous maintenance routines. By prioritizing these factors, professionals can mitigate the risks associated with environmental exposure, enhancing the durability and safety of their constructions. Below, we delve into essential aspects for ensuring robust rot prevention and continual maintenance.

Selecting Durable Materials

Choosing the correct materials is the first and most critical step in preventing rot. Timber, for example, is naturally susceptible to rot unless appropriately selected and treated. Opting for high-quality, pressure-treated wood or naturally rot-resistant species like cedar or cypress is essential. In marine environments, durable materials such as precast concrete and reinforced steel offer significant advantages due to their resistance to moisture and corrosion. The selection process must consider environmental conditions and the specific load requirements of the structure to ensure long-lasting performance and minimal maintenance. By doing so, the threat of rot can be substantially reduced.

Protective Barriers for Exposed Parts

Once durable materials have been selected, applying protective barriers to exposed parts is an effective strategy to further avert rot. Protective coatings or sealants can provide an extra layer of defense against moisture penetration. In marine contexts, for example, anti-corrosive paints or epoxy coatings are indispensable in safeguarding steel and concrete structures from the relentless assault of saltwater immersion and UV rays. These preventative measures not only prolong the material’s lifespan but also minimize the need for costly repairs and replacements down the line. Ensuring that exposed parts are adequately protected is a proactive step in comprehensive rot prevention.

Regular Maintenance and Inspections

Regular maintenance and inspections are the linchpin in the fight against rot. Implementing a systematic maintenance schedule that includes regular inspections can help identify early signs of rot or damage before they escalate into more significant issues. This routine should involve checking for any breaches in protective coatings, signs of moisture ingress, and structural integrity. Prompt addressing of minor issues, such as resealing or applying chemical treatments to vulnerable areas, can prevent more extensive decay. Establishing a vigilant maintenance regime is critical to safeguarding infrastructural investment and ensuring long-term structural stability.

Role of Marine Contractors in Dock Construction

Marine contractors play a pivotal role in ensuring the successful completion of dock construction projects. These professionals bring specialized knowledge and skills necessary for navigating the unique challenges presented by marine environments. From understanding the intricacies of tidal patterns to managing the impact of corrosive saltwater, marine contractors are equipped to handle the complexities that accompany any waterfront construction project. Their expertise ensures not only the structural integrity of docks but also compliance with environmental regulations, which can often be as unpredictable as Mother Nature’s mood swings during a coastal storm.

Importance of Hiring Experienced Professionals

When embarking on dock construction projects, the importance of hiring seasoned professionals cannot be overstated. Experienced marine contractors possess an in-depth understanding of coastal dynamics and the myriad factors that can influence construction timelines and methods. They are adept at selecting appropriate materials that withstand marine degradation, such as reinforced concrete pilings that resist the corrosive effects of salt-water immersion. Furthermore, trained professionals are proficient in using heavy-duty equipment like pile drivers and water jetters to ensure precise installation, avoiding costly delays or structural failures. Engaging experienced contractors ultimately translates to not only a safer, more durable wharf but also a project executed within budget and on schedule—saving everyone from unexpected surprises that can charm their way into coastal construction projects.

Tasks like Seawall Repairs and Boat Lift Installations

Marine contractors are also responsible for a variety of tasks beyond initial dock construction, such as seawall repairs and boat lift installations. Seawall repairs demand a keen understanding of erosion control and marine corrosion resistance. These barriers play a crucial role in maintaining shoreline stability and protecting inland areas from the relentless onslaught of coastal forces. An experienced contractor will assess the damage, select appropriate repair materials, and execute precise reinforcements, effectively safeguarding both the property and its surroundings.

Boat lift installations, on the other hand, require meticulous planning to ensure compatibility with varying water levels and vessel specifications. Contractors must consider aspects like material durability against UV rays and salt-water immersion when selecting components such as fiberglass pilings or pressure-treated wood. Furthermore, the installation process demands a seamless integration with existing dock infrastructure to guarantee operational efficiency and safety. By adeptly managing these tasks, marine contractors extend the longevity and functionality of marine facilities, enhancing both their utility and economic value. Engaging professionals not only ensures these systems are robust but adds an additional layer of reassurance amid the often unpredictable conditions found along coastlines.

Key Questions to Ask Your Dock Builder

Choosing a dock builder for your project is a critical step in ensuring the success and longevity of your dock. Whether you are planning a private dock or an extensive marine expansion, knowing what questions to ask can help you select a contractor who understands your vision and meets industry standards. It’s essential to approach this with the same diligence as any significant construction project. Here are key questions to consider, providing a foundation for a successful builder-client relationship focused on quality, compliance, and timely delivery.

Understanding Project Timeline and Costs

A clear understanding of the project timeline and costs is fundamental when engaging with a dock builder. Start by inquiring about the estimated duration of the project. This includes time for securing permits, design finalization, actual construction, and contingency for weather-related delays—because, let’s face it, coastal weather can be as moody as a teenager. Also, request a detailed breakdown of costs. Ensure it covers all phases of the project from initial design to final inspection, leaving no room for unexpected financial surprises. A transparent cost structure can prevent disputes and align budget expectations.

Ensuring Compliance with Local Regulations

Ensuring that your dock construction project complies with local regulations is not just a legal obligation but a critical aspect of sustainable development. Begin by asking your builder about their familiarity with local zoning laws and environmental regulations. Confirm they have experience navigating the permit acquisition process, as permits often involve rigorous standards regarding environmental impact and construction methodology. Knowing they have a track record in complying with these regulations reassures you that your project won’t face legal hiccups or delays. Compliance also highlights the builder’s commitment to employing best practices in marine construction.

Assessing Builder’s Experience and Past Projects

When evaluating potential dock builders, it’s crucial to assess their experience and review past projects. Start by asking about their experience with projects similar to yours. Whether it’s a private residential dock or a municipal ferry terminal, their expertise in handling similar scope and scale projects is vital for success. Request references and review their portfolio of completed projects. This will showcase their proficiency and creativity while providing insight into their quality of work and attention to detail. Additionally, speaking to past clients can offer a candid view of the builder’s reliability, professionalism, and adaptability to challenges.

Frequently Asked Questions

Dock pilings are installed using three primary methods: jetting (using high-pressure water streams to erode sediment for piling placement in sandy soils), hammering/impact driving (using pile drivers to strike pilings into dense soils and rocky substrates), and drilling (boring precise holes for exact placement in challenging conditions). The method selection depends on soil composition, water depth, load requirements, and environmental conditions. Each technique requires specialized equipment and experienced marine contractors for safe and effective installation.

The best materials for dock pilings include precast concrete (excellent durability for heavy-load applications and saltwater resistance), treated wood (cost-effective with chemical preservatives for smaller projects), Greenheart wood (naturally resistant tropical hardwood for high-load applications), fiberglass (lightweight, UV and marine borer resistant), and steel (highly durable for industrial applications). Material selection depends on environmental conditions, load requirements, budget constraints, and maintenance preferences.

Essential equipment includes pile drivers (vibratory hammers for softer substrates, impact hammers for dense soils and heavy-duty applications), jetting tools and high-pressure pumps (for water-based installation in sandy conditions), drilling equipment (for precise placement in rocky or challenging terrain), cranes for handling heavy materials, and specialized marine construction vessels. The equipment selection varies based on installation method, site conditions, piling materials, and project scale.

Environmental conditions significantly impact method selection: saltwater conditions require corrosion-resistant materials like precast concrete; sandy soils favor jetting techniques while rocky substrates need impact hammering or drilling; water depth influences equipment accessibility; tidal patterns affect installation timing; and load requirements determine material strength needs. Weather conditions, marine life protection, noise regulations, and soil composition all influence the choice between jetting, hammering, or drilling methods for optimal installation results.

Maintenance requirements include regular inspections for signs of marine degradation, rot, or structural damage; applying protective barriers like anti-corrosive paints or epoxy coatings to exposed parts; resealing protective coatings as needed; chemical treatments for vulnerable wood areas; monitoring for marine borer damage; and addressing moisture ingress promptly. Establishing systematic maintenance schedules with qualified marine contractors helps identify issues early, prevents costly repairs, and extends the lifespan of dock infrastructure in harsh marine environments.

Experienced marine contractors possess specialized knowledge of coastal dynamics, tidal patterns, saltwater corrosion effects, and environmental regulations. They understand material selection for marine conditions, proper installation techniques for different soil types, equipment operation in challenging marine environments, permit acquisition processes, and compliance with local regulations. Their expertise ensures structural integrity, prevents costly mistakes, manages project timelines effectively, and delivers durable infrastructure that withstands harsh marine conditions while meeting safety and regulatory standards.