Riser-to-Riser Connections in Stadium Construction: A Comprehensive Guide

In the complex world of stadium seating systems, the connections between structural risers represent one of the most critical engineering decisions. These connections must balance structural integrity, installation efficiency, and long-term durability while accommodating the unique challenges of large-scale venue construction. Drawing from extensive experience in stadium projects, this guide examines the three primary connection methods used in modern stadium construction, providing crucial insights for engineers, contractors, and project managers.

Understanding Riser Connections in Stadium Architecture

Before diving into specific connection methods, it’s essential to understand the role of risers in stadium construction. Risers are the vertical structural elements that create the stepped configuration necessary for tiered seating. These precast concrete components work in conjunction with raker beams to support thousands of spectators while maintaining precise alignment and structural stability.

The connection between adjacent risers is where engineering precision meets practical construction reality. These joints must accommodate manufacturing tolerances, thermal expansion, seismic forces, and the dynamic loads created by crowds. The choice of connection method directly impacts construction speed, project costs, and the long-term performance of the entire seating system.

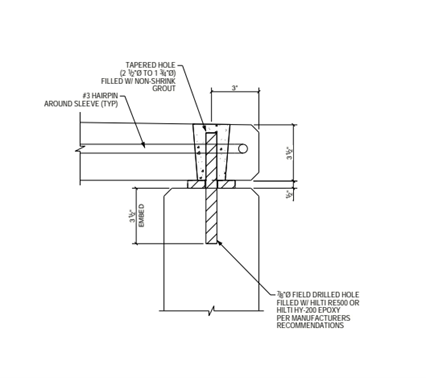

Connection Method #1: Threaded Rod and Grouted Connection

The threaded rod and grouted connection represents the gold standard in riser-to-riser connections, combining structural reliability with installation efficiency. This method has proven itself across numerous stadium projects, consistently delivering the best balance of performance and practicality.

Technical Overview

This connection utilizes high-strength threaded rods that span between adjacent structural risers, anchored within precisely formed pockets. Once the risers are positioned, high-strength, non-shrink grout is pumped into the pockets, creating a monolithic connection that distributes loads evenly while accommodating minor alignment variations.

✓ Advantages

- Maximum installation efficiency: Crews can position risers quickly without precise alignment, reducing crane time and labor costs

- Superior tolerance accommodation: The grouted pockets allow for up to ±1 inch of adjustment in all directions

- Hidden connection points: All structural elements are concealed behind architectural caulking, maintaining clean sight lines

- Color-matched patching: Structural repairs blend seamlessly with the existing precast finish

- Proven reliability: Decades of successful implementations in major venues worldwide

✗ Considerations

- Post-installation work required: Grouting and patching add steps to the construction sequence

- Weather sensitivity: Grouting operations require temperatures above 40°F for proper curing

- Quality control needs: Proper grout mixing and placement require trained personnel

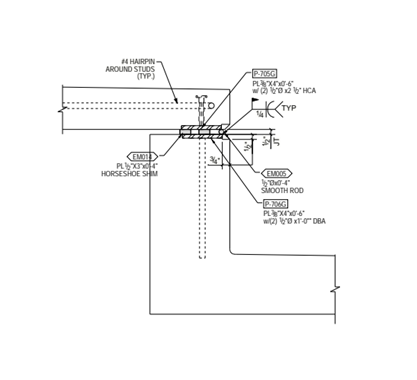

Connection Method #2: Embed-to-Embed Connection

The embed-to-embed connection method relies on steel plates or angles cast directly into the precast risers during manufacturing. These embedded elements are then field-welded to create the structural connection between adjacent units.

Technical Overview

Embedded steel plates or angles are precisely positioned during the precasting process, protruding from the riser edges at predetermined locations. During erection, these embeds are aligned and connected using field welding, creating a direct steel-to-steel load path between adjacent risers.

✓ Advantages

- Moderate tolerance capability: Allows for approximately ±0.5 inch adjustment through oversized holes or slotted connections

- No grouting required: Eliminates weather-dependent wet trades from the critical path

- Immediate structural connection: Welded joints achieve full strength quickly

- Visual inspection possible: Weld quality can be directly observed and tested

✗ Considerations

- Higher material costs: Embedded steel plates and anchors add 15-20% to riser costs

- Exposed welding: Most connections remain visible, requiring aesthetic treatment

- Increased field labor: Certified welders needed for extended periods on-site

- Corrosion protection required: Exposed steel needs ongoing maintenance

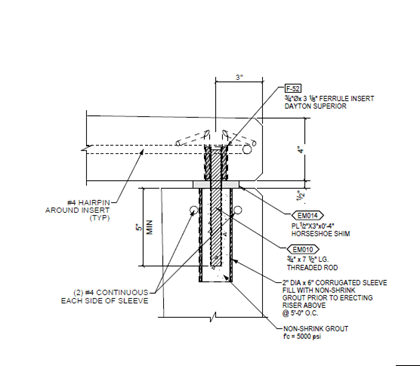

Connection Method #3: Ferrule Insert to Grouted Sleeve Connection

The ferrule insert to grouted sleeve connection represents an attempt to combine the benefits of mechanical connections with grouted systems. However, field experience has consistently shown this method to be problematic in stadium applications.

Technical Overview

This system uses precision-placed ferrule inserts in one riser that must align with grouted sleeves in the adjacent unit. The connection relies on threading reinforcing bars through aligned ferrules into the sleeves, which are then grouted to complete the structural connection.

✓ Limited Advantages

- Theoretical precision: When perfectly executed, provides a strong mechanical connection

- Reduced exposed steel: Most connection elements are embedded within the concrete

✗ Significant Drawbacks

- Zero tolerance accommodation: Requires perfect alignment between risers (±0.125 inch)

- Frequent misalignment issues: Field reports indicate 30-40% of connections require modification

- Expensive repairs: Misaligned connections often require core drilling and rework

- Schedule impacts: Repair work can delay subsequent trades by weeks

- Limited adjustability: Once cast, ferrule positions cannot be modified

Comparative Analysis: Making the Right Choice

| Factor | Threaded Rod & Grouted | Embed-to-Embed | Ferrule Insert |

|---|---|---|---|

| Installation Speed | Fastest | Moderate | Slowest |

| Tolerance Accommodation | ±1 inch | ±0.5 inch | ±0.125 inch |

| Material Cost | Lowest | Highest | Moderate |

| Labor Requirements | Minimal | High (welding) | Very High (repairs) |

| Long-term Maintenance | Minimal | Moderate | High |

| Risk of Delays | Low | Moderate | High |

Implementation Best Practices

For Threaded Rod and Grouted Connections:

- Specify high-strength (minimum 5,000 psi) non-shrink grout

- Ensure pocket dimensions provide minimum 1-inch grout cover around rods

- Install temporary shoring until grout reaches 75% strength

- Use color-matched patching materials from the precast manufacturer

- Implement quality control testing on grout batches

For Projects Considering Alternative Methods:

- Conduct thorough tolerance studies during design phase

- Consider hybrid approaches for specific conditions

- Budget for potential repairs and delays with tight-tolerance systems

- Ensure field crews are properly trained on selected system

Key Takeaway

Based on extensive field experience across numerous stadium projects, the threaded rod and grouted connection method consistently delivers the best combination of installation efficiency, cost-effectiveness, and long-term reliability. While each project has unique requirements, the superior tolerance accommodation and proven track record of this method make it the recommended choice for most stadium seating system applications.

In A Nutshell

The selection of riser-to-riser connection methods represents a critical decision point in stadium construction projects. While the threaded rod and grouted connection emerges as the clear leader in efficiency and reliability, understanding all available options enables informed decision-making based on project-specific requirements. The lessons learned from countless stadium projects underscore a fundamental truth: the most successful connection system is one that acknowledges the realities of field construction while maintaining unwavering structural integrity.

As stadium designs continue to evolve and push the boundaries of engineering possibility, these proven connection methods provide the foundation for safe, efficient, and durable seating systems that will serve venues and their communities for generations to come.