Introduction: Revolutionizing Bridge Construction with Precast Deck Slabs

In an era of urgent infrastructure renewal, the demands on bridge construction are greater than ever: projects must be completed faster, with higher quality, and under stricter safety protocols. The global precast concrete market, valued at USD 105.72 billion in 2023 and projected to grow, reflects a clear industry shift towards more efficient methods, as noted by market analysis. Traditional cast-in-place methods, while familiar, are increasingly unable to meet these modern demands. This is where precast concrete deck slabs emerge not just as an alternative, but as a transformative solution, fundamentally reshaping how we approach bridge construction by delivering an unparalleled combination of speed and on-site safety.

The Core Promise: Unlocking Speed and Uncompromised Safety

The fundamental promise of precast deck slabs is the ability to achieve project acceleration without compromising, and in fact enhancing, safety and structural integrity. By shifting the majority of the deck construction process off-site into a controlled factory setting, projects can bypass many of the variables and hazards that plague traditional builds. This prefabrication approach creates a predictable, streamlined workflow that delivers a superior product to the client faster and more safely.

The Challenge of Traditional Cast-in-Place Methods

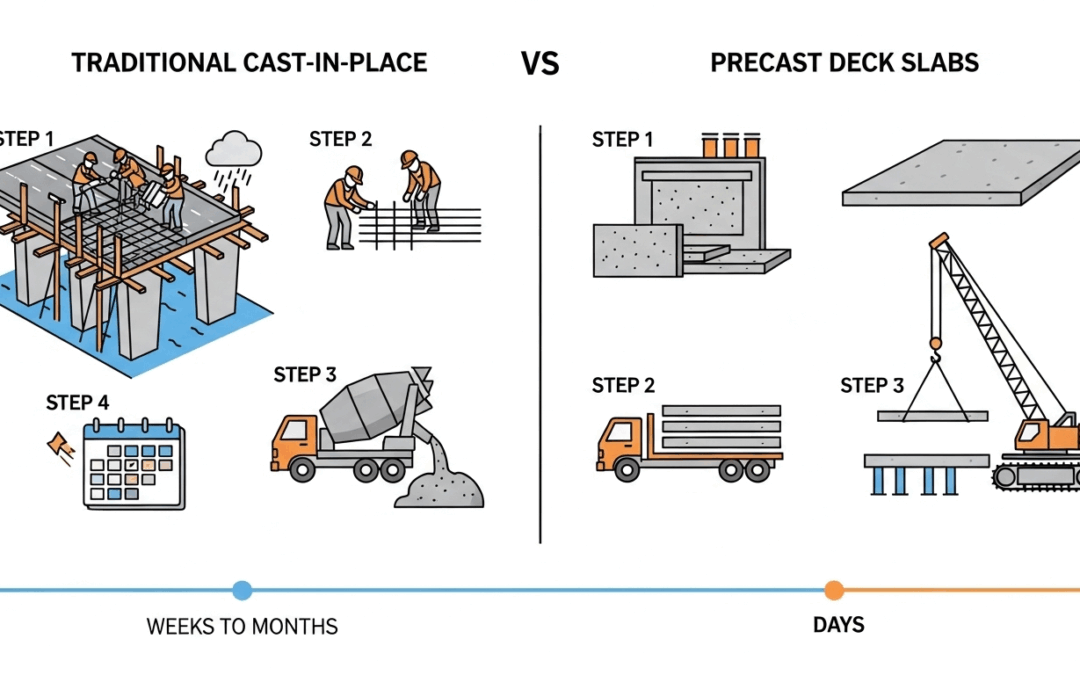

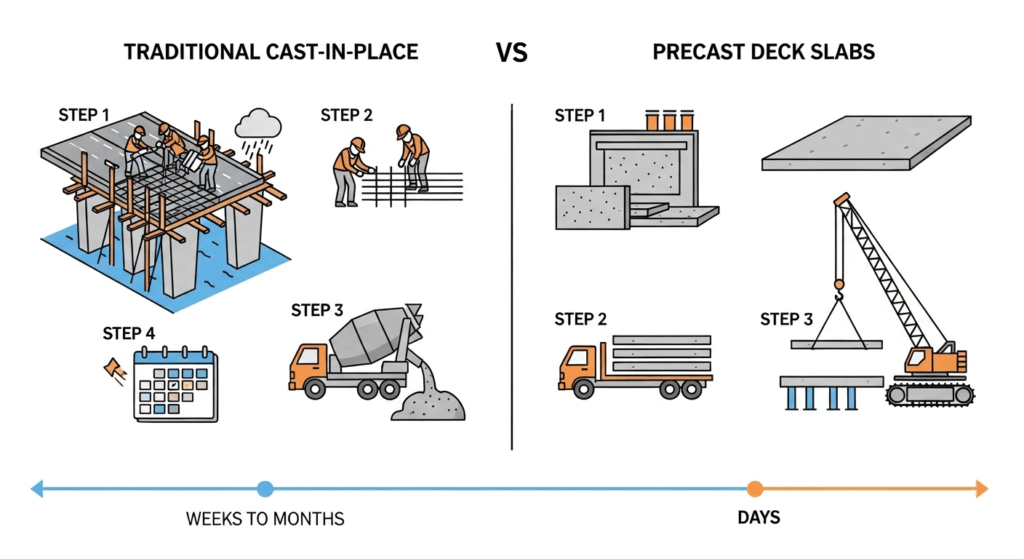

Conventional cast-in-place construction involves building extensive formwork on-site, tying reinforcing steel in place, pouring concrete, and then waiting—often for weeks—for it to cure and gain sufficient strength. This process is labor-intensive, highly susceptible to weather-related delays, and exposes workers to prolonged periods in hazardous environments, such as working at heights over live traffic or active waterways. The extended on-site timeline creates significant public disruption and introduces numerous opportunities for quality control issues.

The Precast Advantage: Building Better, Faster, and Safer from the Ground Up

A comparison of construction workflows: The precast method streamlines the process by moving most of the work off-site, enabling faster installation and minimizing on-site risks.

The precast advantage stems from a fundamental rethinking of the construction sequence. Instead of building piece by piece on-site, the process leverages the efficiencies of manufacturing to produce high-quality components ready for rapid assembly. This shift from on-site construction to off-site manufacturing is the cornerstone of its success.

What Are Precast Deck Slabs?

Precast deck slabs are reinforced concrete panels that form the driving surface of a bridge. They are engineered and manufactured in a specialized factory setting to precise specifications. These finished components are then transported to the construction site and lifted by cranes into their final position on the bridge girders. Once installed and connected, they create a durable, high-performance bridge deck ready for service in a fraction of the time required by traditional methods.

A Foundation of Quality: Material Consistency and Structural Integrity

Manufacturing in a controlled environment is the key to superior quality. In a factory setting, every variable—from aggregate moisture and temperature to concrete mix ratios and curing conditions—is meticulously managed. This rigorous quality control ensures that each precast concrete panel achieves exceptional material consistency, uniform strength, and precise dimensional accuracy. The result is a product with predictable, high-level structural integrity that is difficult to replicate under the variable conditions of on-site construction.

Contrasting with Cast-in-Place Construction

The contrast is stark. Where cast-in-place is sequential and weather-dependent, precast construction is concurrent and climate-controlled. While on-site pouring introduces risks of contamination and inconsistent curing, prefabrication guarantees a product that has been tested and verified before it ever leaves the factory. This proactive approach to quality assurance minimizes the risk of costly rework and ensures the long-term durability of the bridge deck.

Accelerating Project Timelines: The Engine of Efficiency

Speed is one of the most celebrated benefits of precast concrete construction. In a sector where project delays can have cascading financial and social costs, the ability to accelerate schedules is a powerful value proposition for any client. With bridge work in the U.S. having increased by 10.6% year-to-date in late 2023, the demand for faster construction methods is critical.

Shifting Work Off-Site: Concurrent Activities and Reduced Delays

The greatest time savings come from enabling concurrent work streams. While the project site is being prepared—foundations excavated, abutments built, and girders set—the bridge deck slabs are simultaneously being manufactured in the factory. This parallel processing eliminates the significant waiting period associated with on-site formwork and concrete curing. A process that once took weeks of sequential on-site labor is compressed into a matter of days for installation, as demonstrated in projects where precast methods completed a warehouse 3 weeks faster than traditional builds.

Streamlined Installation: Rapid Deployment on Site

Once the precast panels arrive on-site, installation is a matter of logistics and precision. Using cranes, trained crews can lift and set multiple deck slabs in a single day. The process is systematic and highly efficient, resembling an assembly line more than a traditional construction site. This rapid deployment minimizes the time the project site is in a state of disruption, allowing for faster reopening of roadways and reducing the impact on the surrounding community.

Enhanced Project Management and Scheduling

The predictability of prefabrication provides project managers with greater control over scheduling. Because manufacturing is not affected by weather, a key variable is removed from the equation. The client and contractor can rely on a firm delivery schedule for the deck components, allowing for more accurate and dependable project planning. This certainty reduces the “waiting” that often leads to budget creep and timeline extensions, leading to a more streamlined and predictable project response from start to finish.

The Safety Dividend: How Accelerated Construction Directly Boosts On-Site Safety

While speed is a primary driver, the most profound benefit of precast deck slabs is the significant improvement in on-site safety. The construction industry is inherently hazardous, with OSHA reporting that one in ten construction workers is injured annually. By fundamentally changing how and where work is performed, precast construction directly addresses and mitigates many of the sector’s most common risks.

Reducing Worker Exposure: Less Time, Less Risk

The principle is simple: less time spent on-site equals less exposure to risk. Precast construction dramatically reduces the total person-hours required at the project location. By shifting the labor-intensive tasks of formwork, rebar tying, and concrete pouring to a safe, ground-level factory setting, the number of workers needed on the bridge structure itself is minimized. This reduction in exposure time is a critical factor in lowering incident rates.

Inherently Safer Working Conditions During Installation

The nature of the on-site work is also inherently safer. Instead of workers spending weeks building formwork at height, the installation process involves a small, specialized crew working in coordination with cranes to set large, stable components. This minimizes activities like manual material handling in precarious positions and reduces the overall complexity of on-site operations. The process is more controlled, more predictable, and fundamentally less hazardous for the workforce.

Enhanced Public Safety and Reduced Traffic Disruption

Safety benefits extend beyond the work zone. Accelerated construction means shorter road closure durations and fewer traffic detours, reducing the risk of accidents among the traveling public. By compressing the on-site schedule from months to weeks or even days, precast deck slab projects minimize disruptions to community life and commerce, creating a safer environment for everyone.

Engineered for Safety: Precast Deck Slab Design and Quality

The safety advantages of precast deck slabs are not just a byproduct of the process; they are engineered into the product itself. The combination of superior materials, precision manufacturing, and advanced design results in a bridge deck that is built for long-term performance and durability.

Superior Structural Integrity and Durability

The stringent quality control of a factory environment produces a reinforced concrete product with higher compressive strength and lower permeability than is typically achievable on-site. This dense, uniform concrete is more resistant to water ingress, freeze-thaw cycles, and deicing chemicals, which are primary causes of deterioration. This enhanced durability ensures the long-term structural integrity of the bridge deck, reducing the need for disruptive maintenance and ensuring public safety over the structure’s lifespan.

Advanced Materials and Connections for Robust Performance

The precast industry continuously innovates with advanced materials like high-performance concrete (HPC) and corrosion-resistant reinforcement. Furthermore, the connections between precast panels and with the girders are meticulously engineered and tested to ensure they create a monolithic, integrated system. These robust connections are critical for distributing loads effectively and maintaining the overall strength of the bridge structure, meeting or exceeding standards set by bodies like the Federal Highway Administration.

Integrated Safety Features: Beyond the Deck Itself

Prefabrication allows for the integration of safety features directly into the deck panels at the factory. Elements such as curb profiles, drainage scuppers, and connection points for barriers or railings can be cast into the slabs. This eliminates the need for additional on-site work to add these features, further reducing worker exposure and ensuring these critical safety components are installed with factory precision.

Leveraging Technology and Innovation for Peak Performance

Modern precast construction is a high-tech process that leverages digital tools and material science to optimize every stage of design, manufacturing, and installation. This technological integration is key to unlocking the full potential of precast deck slabs for both speed and safety.

Building Information Modeling (BIM): Pre-empting Risks and Optimizing Plans

Building Information Modeling (BIM) is a cornerstone of modern precast projects. By creating a detailed 3D digital model of the entire bridge structure, engineers can pre-emptively identify and resolve potential conflicts before manufacturing begins. BIM allows for precise planning of crane placements, delivery sequencing, and installation logistics, ensuring a seamless on-site fit-up. This digital rehearsal significantly reduces the risk of on-site errors and enhances the safety and efficiency of the assembly process.

Future-Proofing with Advanced Concrete Technologies

The controlled factory setting is the perfect environment for implementing advanced concrete technologies. Innovations such as self-compacting concrete, which ensures void-free placement around dense reinforcement, and ultra-high-performance fiber-reinforced concrete (UHPFRC), which offers exceptional strength and ductility, are more easily and consistently deployed in a precast plant. These materials contribute to lighter, stronger, and more durable bridge decks.

Measuring Success: Quantifiable Benefits in Speed and Safety

The advantages of precast deck slabs are not merely theoretical; they are backed by measurable improvements in project outcomes. Stakeholders can track key performance indicators to quantify the benefits in both project acceleration and safety performance.

Demonstrating Project Acceleration

Project acceleration can be clearly demonstrated by comparing as-built schedules against those for similar cast-in-place projects. Metrics include the reduction in on-site construction days, the number of weather-related delay days avoided, and the overall time from girder placement to bridge opening. These data points provide a clear, quantifiable case for the speed of precast construction.

Tracking and Improving Safety Performance

Safety performance is measured through standard industry metrics such as Total Recordable Incident Rate (TRIR) and Lost Time Injury Frequency Rate (LTIFR). By comparing the safety data from precast installation phases with those from traditional deck construction, a clear correlation emerges: the reduced on-site duration and less hazardous work profile of precast projects lead to demonstrably better safety outcomes.

Real-World Applications and Industry Leaders

Across the country, departments of transportation and forward-thinking contractors are successfully leveraging precast deck slabs to replace aging infrastructure. These projects serve as powerful case studies, demonstrating that accelerated bridge construction is not just a concept but a proven, effective method for delivering high-quality infrastructure faster and more safely, providing immense value to the client.

Conclusion: The Future of Infrastructure is Precast

The challenges facing modern infrastructure demand solutions that are smarter, faster, and safer. Precast concrete deck slabs answer this call directly, offering a proven method to accelerate critical bridge projects while simultaneously raising the bar for on-site safety and long-term quality.

Reaffirming the Synergy of Speed and Safety

The core takeaway is the powerful synergy between speed and safety. By shifting construction to a controlled factory setting, precast technology minimizes on-site risks and streamlines installation. This acceleration is not achieved by cutting corners but by re-engineering the process for maximum efficiency and control, proving that a faster project can and should be a safer project.

A Sustainable and Efficient Choice for Modern Construction

Beyond speed and safety, precast construction offers a more sustainable path forward. The precision of factory production reduces material waste, and the use of optimized designs can lead to significant material savings, as pre-stressed slabs can use up to 45% less concrete than their cast-in-situ counterparts. For clients, contractors, and engineers tasked with building the next generation of resilient infrastructure, precast deck slabs represent the clear choice for efficient, safe, and durable construction.